Choosing the wrong pole material can lead to high maintenance, early failure, or unnecessary costs.

Aluminum poles resist corrosion and reduce maintenance, while steel poles offer strength and cost savings—each has its ideal use case.

Let’s compare both in detail so you can make the right decision for your next outdoor lighting project.

Choosing the Right Pole Material Matters

The material of a light pole affects installation cost, long-term maintenance, safety, and environmental impact.

Understanding the strengths and limitations of aluminum vs. steel will help you choose the best pole for your project's needs.

In my years of working on projects across Africa—from coastal towns to inland industrial parks—I’ve learned there’s no one-size-fits-all. But there is a smart choice based on your environment, budget, and application.

Quick Comparison Table – Aluminum vs. Steel Poles

Here’s a side-by-side comparison of the most important factors:

| Feature | Aluminum Pole | Steel Pole |

|---|---|---|

| Weight | Lightweight, easy to transport | Heavy, needs lifting equipment |

| Corrosion Resistance | Excellent (natural oxide layer) | Needs galvanization or coating |

| Strength | Moderate, best for light to medium loads | High, supports heavier fixtures |

| Initial Cost | Higher upfront | Lower upfront |

| Lifecycle Cost | Lower (minimal maintenance) | Higher (rust treatment needed) |

| Maintenance Needs | Low (no rust) | High (painting, rust removal) |

| Lifespan | 20–30 years with little intervention | 15–25 years with proper care |

| Sustainability | Fully recyclable, lower carbon footprint | Energy-intensive production, more waste |

Durability and Weather Resistance

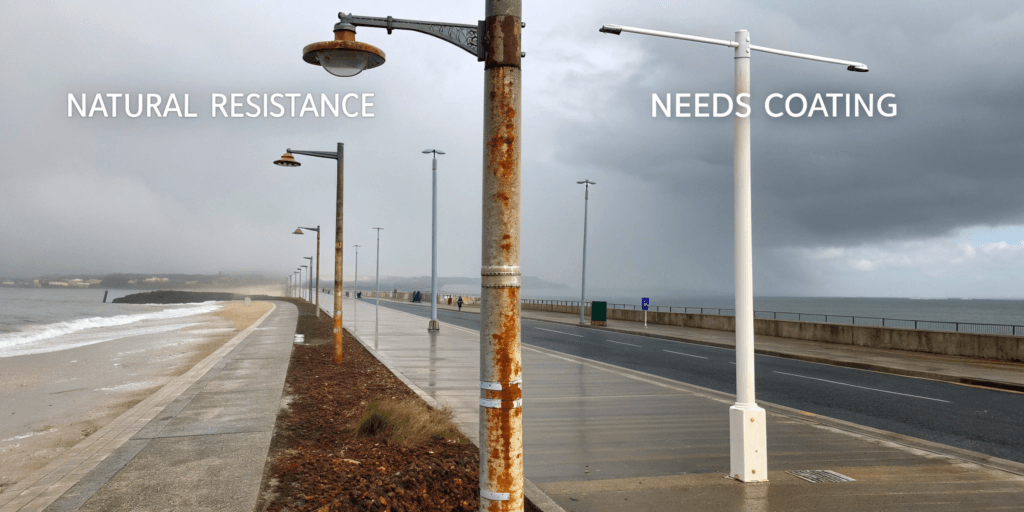

In harsh outdoor environments, corrosion resistance is a critical factor.

Aluminum poles resist salt, moisture, and humidity better than steel.

- Aluminum: Natural anti-corrosion properties make it ideal for coastal, humid, or tropical areas

- Steel: Strong but rusts quickly if uncoated; needs galvanization or epoxy treatment

📍 Real-world example:

We installed aluminum poles in a seaside village in Ghana. Ten years later, they still look new. Meanwhile, a nearby highway with bare steel poles showed severe rust within four years—despite a higher wind rating.

Weight and Installation

Transportation and installation are major cost factors—especially in remote areas.

Aluminum poles are easier to handle and install, while steel poles are more robust and stable after setup.

-

Aluminum:

- Light weight = faster setup

- Ideal for remote or labor-sensitive projects

-

Steel:

- Heavier, needs cranes or hoists

- Good for permanent infrastructure where site access is easy

🛠 Tip: If your project involves high-mast poles or multiple installations in urban centers, factor in the equipment cost for handling steel poles.

Strength and Wind Load Performance

Pole strength affects how well it handles the weight of light fixtures, banners, and wind pressure.

Steel poles outperform aluminum in high-load or high-wind situations.

- Steel: Best for highway lighting, stadiums, and heavy fixtures

- Aluminum: Strong enough for residential streets, walkways, and small parks

📌 Recommendation by height/load:

| Pole Height | Best Material |

|---|---|

| 5–8m | Aluminum or steel |

| 9–12m | Steel recommended |

| 13m+ | Steel with reinforced base |

In storm-prone zones, we always advise wind-load-tested steel poles, especially for double-arm designs.

Cost Analysis – Initial Cost vs Lifecycle Cost

Choosing based on price alone can be misleading.

Aluminum costs more at first but often saves money over time.

-

Steel Pole

- Cheaper up front

- More frequent repainting and rust-proofing

- Shorter service life without strict maintenance

-

Aluminum Pole

- More expensive initially

- Minimal maintenance

- Longer usable life = better ROI

💰 ROI Snapshot:

| Factor | Steel Pole | Aluminum Pole |

|---|---|---|

| 10-Year Maintenance Cost | $300+ | $100 or less |

| Expected Lifespan | 15–20 years | 25–30 years |

| Total 10-Year Cost | Higher | Lower |

Maintenance Requirements and Longevity

Maintenance isn’t just a cost—it affects public safety and reliability.

Aluminum poles require far less upkeep and deliver more consistent long-term performance.

-

Steel:

- Must monitor for rust

- Requires periodic painting or recoating

- More likely to need replacement earlier

-

Aluminum:

- Needs only basic inspections

- No rust risk, even in rainy or coastal zones

📅 For 20+ year projects, aluminum pays off. That’s why we always recommend it for city parks, universities, and residential communities.

Sustainability and Environmental Impact

Green projects are increasingly required to meet environmental standards.

Aluminum is more eco-friendly than steel in production and recycling.

-

Aluminum:

- Up to 95% recyclable

- Lower carbon footprint

- Compliant with many government sustainability mandates

-

Steel:

- Produces more CO₂ during manufacturing

- Requires more energy to recycle

🌿 In government tenders, we’re often asked to show the environmental impact report. Choosing aluminum has helped our bids meet regulatory criteria in Togo and Uganda.

Application Scenarios – Which Pole Works Best for Your Project?

Different projects need different materials.

Choose based on location, fixture type, and expected wear.

| Application Area | Recommended Material |

|---|---|

| Coastal zones | Aluminum |

| Urban residential areas | Aluminum |

| City parks & footpaths | Aluminum |

| Industrial zones | Steel |

| Highways & main roads | Steel |

| Large parking lots | Steel |

| Heavy fixture applications | Steel |

🏷️ If you’re sourcing for a housing development or park, go with aluminum. For infrastructure projects like interchanges or airports, steel is still the go-to.

Expert Recommendation: How to Choose the Best Pole for Your Outdoor Lighting Project

Still unsure? Here’s a simple checklist to guide your decision.

Checklist: Key Factors to Consider

- ❓ Is the site near the ocean or exposed to high moisture? → Choose aluminum

- ❓ Will the pole carry heavy lights or signage? → Choose steel

- ❓ Is installation labor cost a concern? → Choose aluminum

- ❓ Are you working with a long-term project (20+ years)? → Aluminum pays off

- ❓ Is upfront cost more important than maintenance? → Consider steel

- ❓ Does your project need to meet green certification? → Aluminum is best

🎯 Pro Tip: When in doubt, ask your supplier for wind zone ratings and corrosion resistance certificates.

Conclusion – Which One Should You Choose?

Both materials have their strengths.

Choose aluminum for corrosion resistance, low maintenance, and lightweight installation. Choose steel for strength, stability, and budget-sensitive projects.

For the best results, partner with a manufacturer who understands your local conditions and can customize your poles to meet exact needs.

📞 Reach out to us for tailored lighting pole recommendations. We'll help you match the right material to your environment, your project scope, and your budget.