There is no single “best” solar street light manufacturer. The right choice depends on your road class, required autonomy nights, and—most importantly—the supplier’s ability to provide a tender-ready documentation pack (IES/LDT files, UN38.3 battery compliance, and structural drawings).

To simplify procurement, this guide shortlists global manufacturers by project strengths and gives you a reusable selection scorecard, a comparison table, and a tender checklist you can copy into your next RFQ.

Quick Summary: Choosing a Project-Ready Manufacturer

| Project Need | Top Recommended Manufacturers (Shortlist) | Key Verification Required |

|---|---|---|

| High-Speed Roads / EPC | Signify (Philips), Schréder, Fonroche Lighting | IES optics + DIALux/AGi32 simulation |

| Smart Cities / IoT | Leadsun, Sunna Design, Sol (Sol Inc.) | Remote monitoring dashboard access + data fields |

| Remote / Rural Off-Grid | SEPCO, Photinus, SOKOYO | Autonomy model + dimming curve + battery aging |

| Hybrid / Grid-Tied | Signify, Havells, Sunlurio | AC/DC interface logic + safety + commissioning checklist |

Download EPC Scoring Matrix (.XLS)

Download Tender Submittal Checklist (.PDF)

Last updated: January 2026

Which manufacturers should you shortlist first for EPC tenders?

If your tender can fail due to missing documents, shortlist manufacturers who can prove optics (IES/LDT + simulation), battery transport compliance (UN38.3/MSDS), and provide pole/foundation drawings—not just lumen claims. Below is a curated shortlist grouped by strength. Keep it tight: 5–8 names per bucket is enough for a serious bid evaluation.

Which manufacturers are best for government and EPC tenders where documentation decides approval?

Documentation-strong manufacturers are not always the cheapest—but they usually reduce rework, clarification cycles, and approval delays. These are common candidates in tender-heavy environments:

- Signify (Philips)

- Schréder

- Fonroche Lighting

- Sunna Design

- SEPCO (Solar Electric Power Company)

- Carmanah (often seen in safety/traffic-adjacent procurement)

Which manufacturers are best for smart monitoring, IoT, and remote operations?

If your lights are spread across districts or rural corridors, monitoring can save more money than it costs—because you stop driving blind. Common candidates to evaluate for smart/IoT-heavy specs:

- Leadsun

- Sunna Design

- Sol (Sol Inc.)

- Schréder (smart lighting heritage; verify solar monitoring scope per project)

- Fonroche Lighting (verify monitoring scope per market and model)

Which manufacturers are best for rural off-grid roads with high autonomy and low maintenance?

Rural/off-grid projects fail when autonomy is brochure math. Choose suppliers who can show an energy model (worst-month irradiance + dimming curve + battery aging). Common candidates for autonomy-heavy projects:

- SEPCO

- Photinus

- Fonroche Lighting

- SOKOYO

- Yangzhou Bright Solar (export manufacturing; verify docs before shortlist lock)

Which manufacturers are best for hybrid or grid-tied projects?

Hybrid projects need clarity on AC/DC interfaces, switching logic, safety protections, and commissioning—otherwise the “hybrid” label becomes a dispute. Common candidates to evaluate:

- Signify (Philips)

- Schréder

- Havells

- Sunlurio

Which regional leaders matter most in real procurement?

Procurement is local—even when brands are global. Your “best” manufacturer is often the one that can deliver spares, answer submittals fast, and match your BOQ without confusion. A practical regional lens:

- Europe: Schréder, Sunna Design, Fonroche Lighting, Photinus, Signify

- North America: SEPCO, Sol (Sol Inc.), Carmanah

- China / East Asia supply base: SOKOYO, ALLTOP, Yangzhou Bright Solar, Sunlurio

- India / South Asia: Havells (plus tender-approved local lists depending on your state/utility)

What is a “tender-ready” solar street light submittal?

A tender-ready submittal is a complete technical package that lets engineers verify performance before purchase—and lets procurement defend the award decision. If a supplier can’t produce this pack early, you’ll feel the pain later during approvals, shipping, installation, and handover.

A tender-ready submittal is a comprehensive technical package that allows engineers to verify performance before purchase. It must include:

- Photometric Files: IES/LDT files for DIALux/AGi32 simulation

- Battery Compliance: UN38.3 and MSDS certificates for transport (plus packing guidance)

- Energy Model: sizing based on autonomy nights and dimming curves (assumptions disclosed)

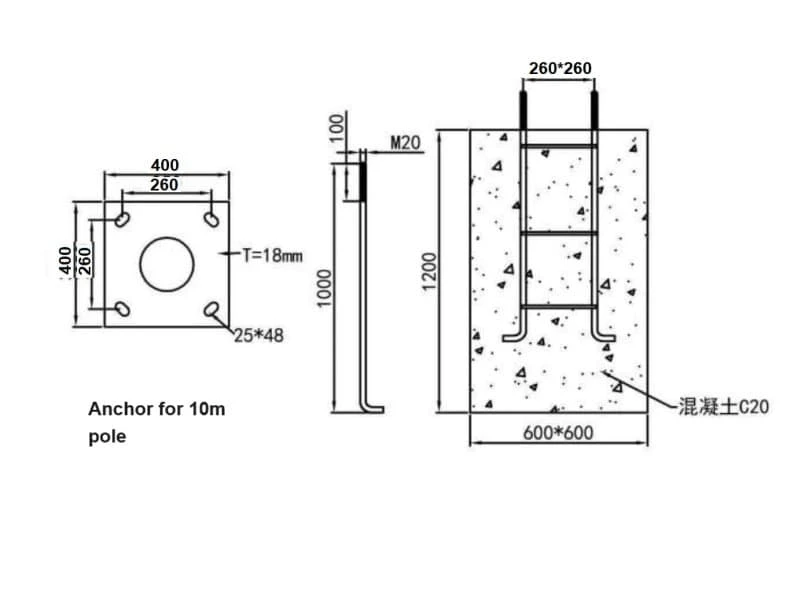

- Structural Proof: wind-load and corrosion-aligned pole + foundation drawings (anchor bolt template included)

- Warranty Split: clear coverage for battery, LED/luminaire, and controller

Download the Tender Checklist (.PDF)

Copy-Paste RFQ Email Template (.PDF)

How did we select and rank these manufacturers for EPC tenders?

Most “top manufacturer” lists are just brand dumps. EPC teams don’t need a brand dump—they need a repeatable method to reduce risk. The scoring approach below is designed for tender committees, consultants, and project managers who must justify decisions and avoid costly rework.

Over the last 15 years working across African infrastructure and solar lighting programs, I’ve watched the same pattern repeat: projects don’t fail because LEDs are “bad.” They fail because the system design is inconsistent, the documentation is weak, and no one can prove what was promised. If you’re an EPC team, you already know how this movie ends: a dozen clarification emails, a delayed shipment due to missing battery documents, a site team guessing pole spacing, and finally a client who says “not as per spec.”

This is why the methodology is built around submittal integrity. I score suppliers by what they can prove on paper and execute in hardware. I also separate “best fit” by scenario instead of pretending one company is best for everything. A brand can be excellent for a smart city dashboard and only average for rural autonomy. That’s normal, and your scoring system should reflect it.

What scoring criteria should your selection scorecard include?

Use 8–10 criteria, score each 0–5, then rank by project scenario (tender-heavy, rural off-grid, smart monitoring, hybrid). This gives you defensible procurement logic and reduces internal arguments.

Recommended criteria (0–5 each):

| Scoring Criteria | What a “5” looks like in real tenders |

|---|---|

| Photometric credibility | IES/LDT files + photometric plots + simulation support (DIALux/AGi32-ready) |

| Battery system maturity | LiFePO₄ with BMS, cycle-life assumptions stated, replacement pathway defined |

| Battery transport compliance | UN38.3 + MSDS + packing guidance provided before shipment |

| Controller & MPPT | clear controller spec, MPPT behavior stated, dimming profiles configurable |

| Autonomy & energy design | autonomy nights + dimming curve + worst-month irradiance + battery aging disclosed |

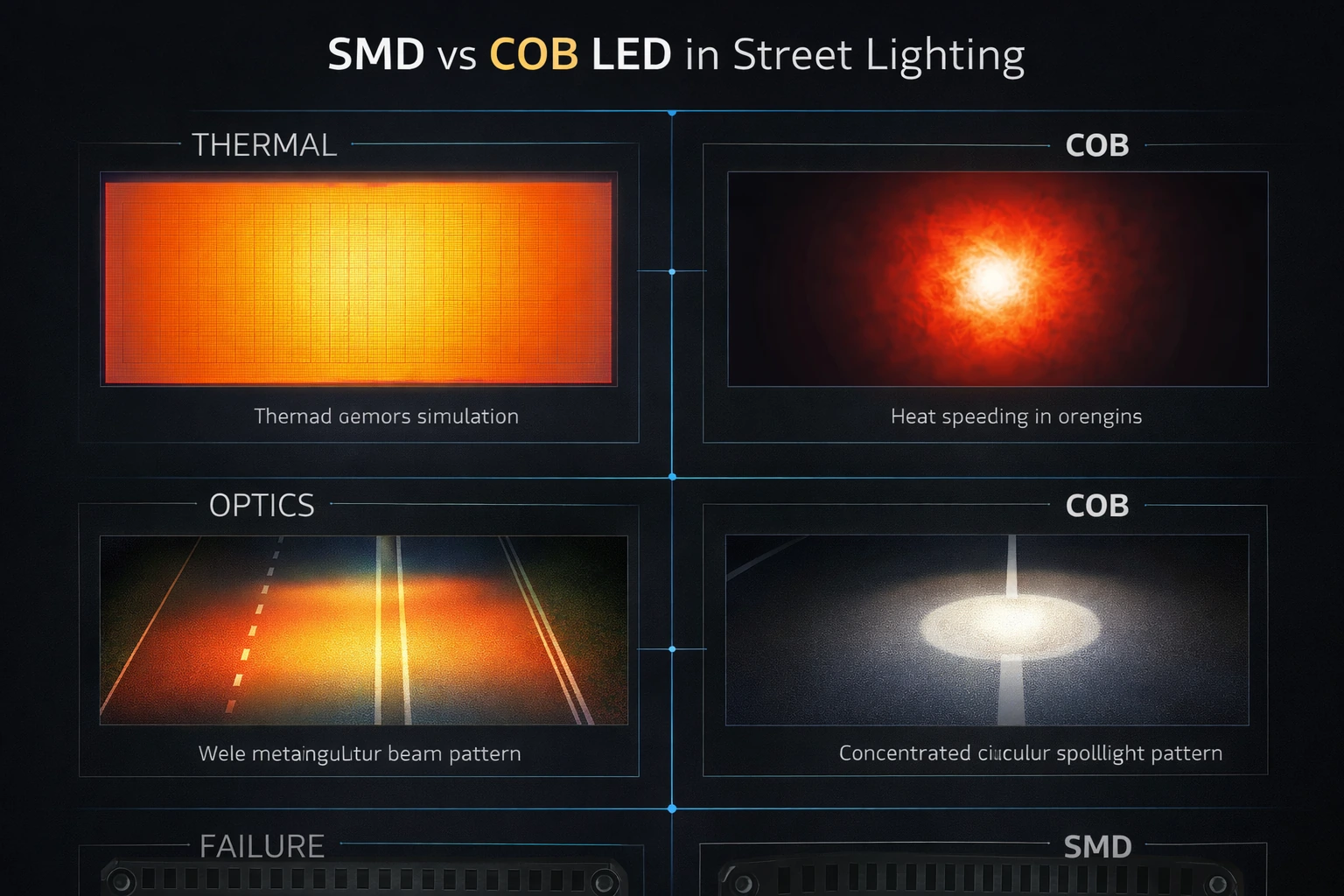

| Luminaire engineering | IP/IK clarity, thermal path explanation, practical derating or longevity thinking |

| Pole & foundation support | drawings, anchor bolt templates, wind and corrosion assumptions included |

| Compliance & test reports | market-appropriate test reports and consistency across batches/models |

| After-sales & spares strategy | modular maintenance approach, spares list, lead times, escalation path |

| Warranty clarity | component-split warranty with enforceable wording and process |

Get the Supplier Scorecard (.XLS)

What should you exclude immediately (even if the price is attractive)?

Exclude suppliers that cannot provide core engineering files or transport compliance documentation early. In EPC tenders, missing documents are not “admin issues”—they become schedule and cost issues.

Common exclusion triggers:

- No IES/LDT files or refusal to share pre-award

- No UN38.3/MSDS for battery transport

- “12 hours lighting” claims with no autonomy model or assumptions

- No pole/foundation drawings or no clarity on wind/corrosion assumptions

- One-line warranty without component split

- No commissioning checklist (meaning acceptance becomes an argument)

What does a comparison table look like that EPC teams can actually reuse?

A good comparison table doesn’t crown a single winner—it maps manufacturers to best-fit scenarios and shows what you must verify. This table is designed to be copied into an internal evaluation memo or tender clarification sheet.

| Company / HQ | Strength | Typical Products | Documentation Pack (what to demand) | Smart Control | Battery & Transport Docs | Warranty | Best-Fit Projects |

|---|---|---|---|---|---|---|---|

| Signify (Philips) / Global | Tender-heavy, roadway heritage | AIO / AIT | IES/LDT, simulation, manuals, BOM/BOQ mapping | verify per model | UN38.3 + MSDS | component split | city roads, municipal programs |

| Schréder / Europe | Roadway engineering | roadway + solar options | IES/LDT, simulation, drawings, acceptance checklist | verify scope | UN38.3 + MSDS | component split | arterial roads, strict roadway targets |

| Fonroche Lighting / Europe | Large solar deployments | standalone solar | energy model, drawings, submittal discipline | verify | UN38.3 + MSDS | component split | mass rollouts, campuses, road programs |

| Sunna Design / Europe | Connected public solar | standalone solar | IES/LDT, energy model, monitoring description | verify dashboard | UN38.3 + MSDS | component split | smart public lighting, districts |

| Leadsun / Australia | Monitoring + operations | solar street/area | monitoring spec + commissioning process | strong focus | UN38.3 + MSDS | component split | estates, campuses, distributed assets |

| Sol (Sol Inc.) / USA | Monitoring + asset management | solar lighting systems | platform spec + asset reporting fields | strong focus | UN38.3 + MSDS | component split | municipalities with SLA reporting |

| SEPCO / USA | Off-grid design discipline | solar roadway/area | energy model + drawings + manuals | verify | UN38.3 + MSDS | component split | remote roads, industrial yards |

| Carmanah / Canada | Compliance mindset | safety/traffic + some area | compliance docs + acceptance criteria | verify | UN38.3 + MSDS | component split | corridors, safety-driven specs |

| Photinus / Europe | Self-sustaining systems | solar outdoor lighting | autonomy model + optics proof | verify | UN38.3 + MSDS | component split | harsh climates, autonomy-heavy sites |

| SOKOYO / China | Solar specialist supply | AIO / split / hybrid | full tender pack required | verify | UN38.3 + MSDS | component split | standard road packages, cost-sensitive tenders |

| ALLTOP / China | Broad SKU supplier | AIO / split | full tender pack required | verify | UN38.3 + MSDS | component split | distributor-led projects |

| Yangzhou Bright Solar / China | Export manufacturing | solar street systems | full tender pack required | verify | UN38.3 + MSDS | component split | standard packages with strict verification |

| Havells / India | India tender ecosystem | solar street solutions | IES/LDT + manuals + controller profile | verify | UN38.3 + MSDS | component split | state procurement, mixed portfolios |

| Sunlurio / China | EPC integration focus | solar + AC + poles | full submittal pack + BOQ mapping + drawings | verify | UN38.3 + MSDS | component split | Africa/ME tenders needing poles + kits |

Download the Comparison Scorecard (.XLS)

Which manufacturer profiles matter most, and what should you ask each one?

A manufacturer profile should read like an approval checklist—not an advertisement. Use these “engineering delivery cards” to standardize RFQs and stop vendors from hiding behind glossy brochures.

Is Signify (Philips) best when your tender needs recognized catalogs and structured submittals?

Best for: tender-heavy municipal projects where structured documentation reduces approval friction.

Project-fit checklist: arterial/collector roads, municipal upgrades, consultant-led approvals.

Docs to ask for: IES/LDT, simulation report, energy model assumptions, UN38.3/MSDS, pole interface drawings, commissioning checklist.

Red flags: relying on “brand comfort” instead of verifying the exact model’s photometry and shipping documents.

Is Schréder best for strict roadway targets where uniformity matters?

Best for: roadway-class projects with strict uniformity and performance targets.

Project-fit checklist: arterial roads, higher wind zones, consultant-led specs.

Docs to ask for: IES/LDT and spacing guidance, wind/corrosion assumptions, pole/foundation interface details, acceptance checklist.

Red flags: vague “solar solution” claims without specific files for the model being bid.

Is Fonroche Lighting best for large-scale standalone solar rollouts?

Best for: large deployments where repeatability and system accountability matter.

Project-fit checklist: mass rollouts, campuses, industrial estates, remote grid-poor corridors.

Docs to ask for: autonomy model with worst-month irradiance assumptions, dimming curve, IES/LDT files, structural drawings, UN38.3/MSDS, spare parts plan.

Red flags: “works all year” messaging without disclosed assumptions and acceptance criteria.

Are Leadsun and Sol (Sol Inc.) best when monitoring is part of the business case?

Best for: distributed assets where downtime visibility and SLA reporting matter.

Project-fit checklist: estates, municipalities with performance reporting, campuses, scattered rural assets.

Docs to ask for: dashboard data fields (battery SOC, PV harvest, faults, runtime), connectivity assumptions, commissioning process, spares for controllers/sensors.

Red flags: “smart” features that depend on connectivity you don’t actually have on site.

Is SEPCO a strong candidate for autonomy-heavy off-grid roadway and area lighting?

Best for: off-grid road/area lighting where the system must be engineered conservatively.

Project-fit checklist: remote roads, industrial yards, perimeter roads, airports, ports.

Docs to ask for: energy model with dimming curve and aging assumptions, optics proof via IES/LDT, shipping compliance, drawings and installation manuals.

Red flags: unclear responsibility boundaries between luminaire supplier, pole supplier, and installer.

Is Sunlurio the right manufacturer when your EPC tender needs a complete “submittal pack”?

Best for: tender-driven road projects where you want documentation discipline + system integration (especially when poles/foundations and solar kits must match civil assumptions).

Docs to ask for (pre-award):

- IES/LDT files for the exact luminaire and lens configuration

- DIALux/AGi32 simulation report using your road geometry and mounting assumptions

- Autonomy calculation with disclosed assumptions (worst-month irradiance, dimming curve, battery aging)

- UN38.3 + MSDS + packing declaration for shipped battery configuration

- Pole drawings + anchor bolt template + corrosion notes

- Component-split warranty (battery/luminaire/controller) + spares list and lead times

- Installation manual + commissioning checklist + troubleshooting guide

Should you evaluate China-based manufacturers like SOKOYO, ALLTOP, and Bright Solar for EPC projects?

Best for: cost-sensitive, standardized packages when you enforce strict documentation gates.

Docs to ask for: full tender pack (IES/LDT, energy model, UN38.3/MSDS, drawings, manuals, warranty split).

Red flags: mid-production BOM changes, vague “equivalent to” language, and missing transport documents.

How do you choose the right manufacturer for your project (a practical EPC workflow)?

Selection should follow a strict engineering workflow: define targets, size energy honestly, verify optics, lock structural assumptions, then approve the tender pack. If you do it in this order, you reduce rework and protect your schedule.

Step 1 — How do you define road class and lighting targets before you talk to suppliers?

If you don’t define what “good lighting” means, every vendor bids a different reality. Start with road class and geometry. Even if your consultant will finalize later, you need preliminary targets for meaningful simulations.

Define early:

- road class (arterial/collector/local) or national category

- road width, lanes, shoulders, sidewalks, medians

- target maintained illuminance and uniformity (if applicable)

- preliminary pole height range, arm length, spacing range

- environmental class (coastal corrosion, dust, flood risk, vandalism risk)

Step 2 — How do you size PV and battery by autonomy nights and dimming curve (not “12 hours”)?

Autonomy is the heart of solar street lighting—brochure autonomy is the fastest path to failure. Your RFQ should require an energy model with disclosed assumptions.

Require these inputs:

- autonomy nights (risk-based: access difficulty, client expectations, rainfall patterns)

- dimming curve hour-by-hour (don’t accept vague “smart dimming”)

- worst-month solar irradiance assumption for the site (not annual average)

- battery aging assumption (end-of-life capacity)

- temperature constraints and charge behavior (hot climates matter)

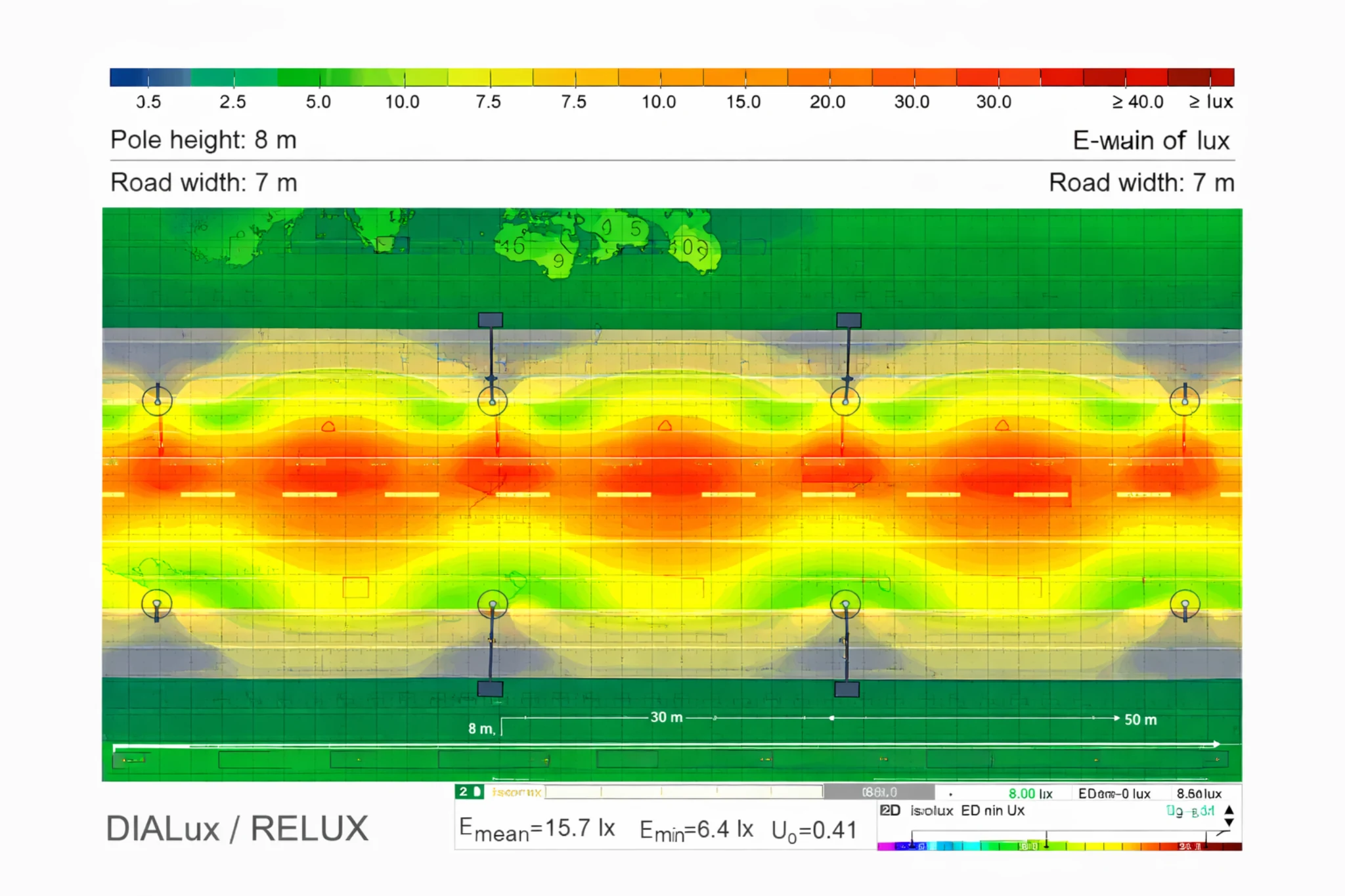

Step 3 — How do you verify optics with IES/LDT and simulation instead of datasheet lumens?

Lumens are not a road design tool—optics distribution and simulation are. Two luminaires with identical lumens can produce completely different uniformity and glare outcomes.

Require:

- IES/LDT files for the exact configuration

- DIALux/AGi32 simulation report based on your geometry and mounting assumptions

- distribution type intent (roadway lens options)

- maintained output assumptions (not only initial output)

Step 4 — How do you confirm pole/foundation, wind, and corrosion assumptions before award?

Poles and foundations are where street lighting projects quietly fail—especially in coastal or high-wind corridors. Solar assemblies add sail area and change load cases.

Confirm:

- design wind speed and standard reference

- corrosion class and coating spec (galvanization thickness, paint systems, fastener materials)

- pole drawings and anchor bolt templates

- foundation drawings or minimum parameters

- cable routing, access doors, anti-theft provisions

- transport constraints and packaging plan

Step 5 — How do you lock the tender documentation and acceptance checklist so handover is smooth?

Write acceptance criteria before the PO, not after installation. Otherwise you’ll negotiate “what success means” on site.

Lock:

- simulated layout vs installed layout verification plan (sample audit points)

- dimming profile verification method

- document pack delivery timeline (before shipment)

- warranty split and replacement process

- spare parts quantities and lead times

- commissioning checklist sign-off steps

What should your tender & submittal document pack include?

This checklist is the most practical part of the page—copy it into your RFQ and stop fighting approval battles later. EPC teams live and die by submittals.

Tender/submittal checklist (copy/paste)

- ☐ Lighting simulation report (PDF) for your road geometry

- ☐ IES/LDT files + photometric plots (distribution and mounting assumptions)

- ☐ BOM + BOQ mapping to tender line items

- ☐ Battery UN38.3 + MSDS + packing declaration (shipping method note included)

- ☐ Controller spec + MPPT description + dimming profile options

- ☐ Luminaire IP/IK ratings + thermal notes (if available)

- ☐ Pole and foundation drawings + anchor bolt template + corrosion recommendations

- ☐ Installation manual + commissioning checklist + troubleshooting guide

- ☐ Component-split warranty statement (battery / luminaire / controller)

- ☐ Spare parts list + recommended spares quantity + lead time

- ☐ After-sales contacts + escalation path + training/hand-over plan

Download 1-Page Tender Checklist (.PDF)

Download RFQ Template (.PDF)

What are the most common mistakes and red flags in solar street light procurement?

Most failures are procurement failures disguised as technology failures. The pattern is simple: a project buys a “bright light,” then discovers it was missing the engineering proof to make it work in the real world.

Why is “high lumens” without IES/LDT a serious red flag?

Because roads are about where light lands, not how much light exits the fixture. Without IES/LDT and simulation, you can’t prove uniformity, glare control, or real-world spacing.

Why is “12 hours lighting” a misleading claim without an autonomy model?

Because “12 hours” can be achieved by aggressive dimming or unrealistic assumptions. The client hears “bright all night.” The vendor means “some light exists all night.”

Why do battery transport documents (UN38.3/MSDS) affect project schedules so much?

Because missing compliance documents can block shipping, delay clearance, and trigger storage costs. You don’t want to learn about UN38.3 at the port.

Why is a one-line warranty dangerous?

Because it’s not enforceable. Solar street lights are systems with different failure modes, and warranty terms must be split by component.

Why do spares and modularity matter more than people admit?

Because maintenance is inevitable—especially after year 5. Batteries age, controllers can fail, and connectors corrode. If you didn’t plan spares, downtime becomes political.

FAQ: What do EPC teams ask most about solar street light manufacturers?

Who is the largest solar street light manufacturer?

“Largest” depends on how you measure it: global lighting conglomerate scale, solar-street-light specialist scale, or regional export volume. For EPC tenders, a better question is: who is most reliable for my scenario, with proof through submittals, lead time, and spares.

What documents should I request before tender approval?

At minimum: IES/LDT + simulation report, UN38.3/MSDS, autonomy model (with assumptions), pole/foundation drawings, installation/commissioning checklist, and a component-split warranty.

How many nights of autonomy are recommended?

It’s a risk decision. Urban sites with easy maintenance access may accept fewer nights. Remote sites often require more autonomy because downtime is harder to fix.

All-in-one vs split solar street lights: which is better for projects?

All-in-one simplifies installation. Split systems can improve serviceability and allow more flexible PV orientation. Choose based on theft risk and maintenance strategy.

How do I verify lumen claims?

Start with IES/LDT files and a simulation report based on your road geometry and mounting assumptions. Lumens without optics proof is not a tender-grade specification.

What is MPPT and why does it matter?

MPPT controllers optimize PV harvesting under changing conditions. In tender terms, MPPT matters because better harvesting can improve autonomy margins—if the energy model is honest.

How do I choose pole height and spacing?

Use your road class and target lighting performance, then validate with simulation. Pole height and spacing affect both photometry and energy sizing.

What warranty terms are normal for EPC projects?

Normal is a component-split warranty with enforceable wording and a defined replacement process. Anything vague becomes a dispute later.

How do we evaluate these manufacturers (expert methodology)?

We evaluate manufacturers based on “Submittal Integrity,” not marketing claims. We check whether the IES/LDT files match the physical optic, whether the autonomy model discloses its assumptions (dimming curve, worst-month irradiance, battery aging), and whether structural drawings align with wind and corrosion conditions. We prioritize suppliers who provide transparent spare parts lists and modular designs that allow battery replacement 5–8 years post-installation.