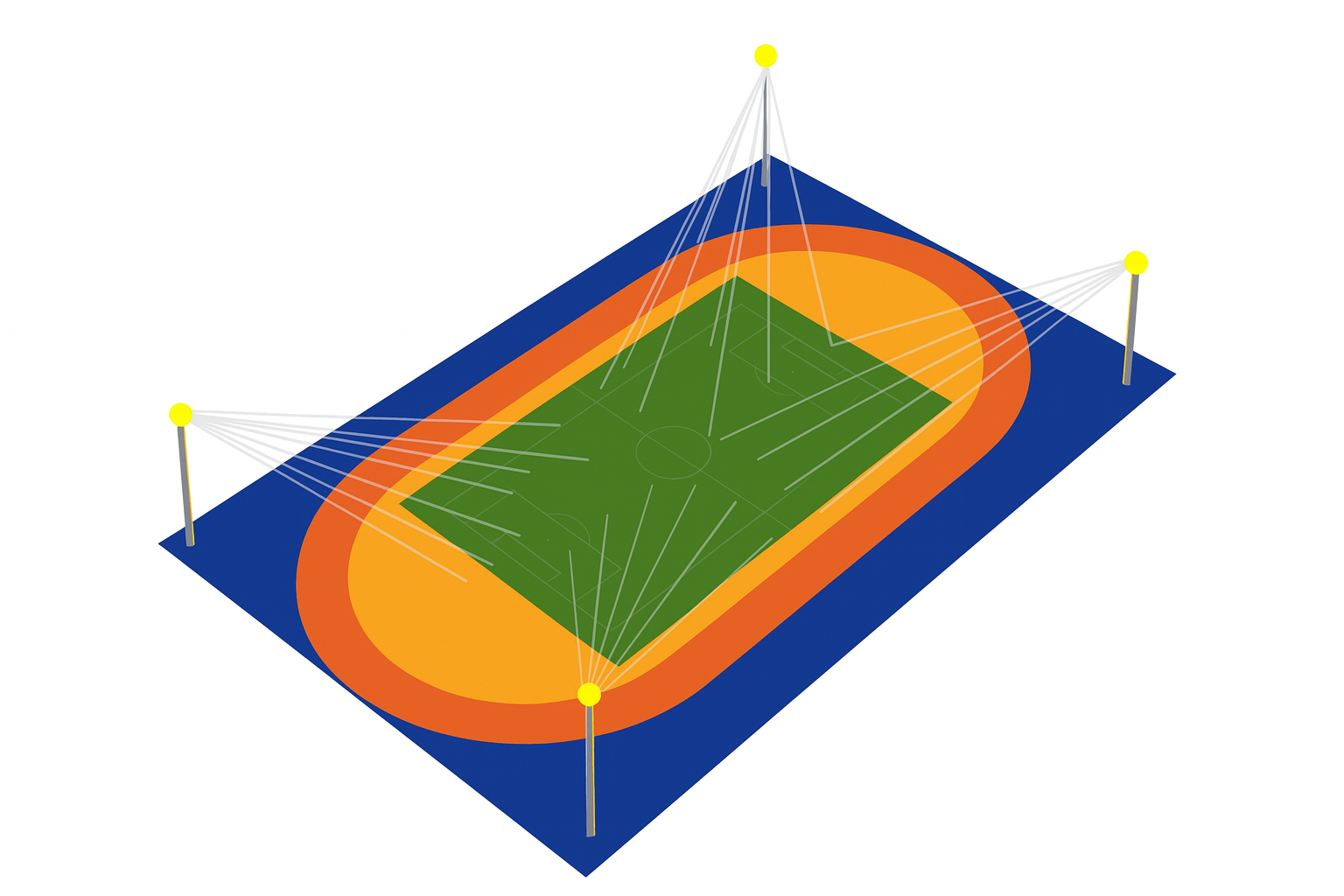

High mast lighting coverage area is the ground space effectively illuminated by fixtures mounted on tall poles (typically 20–45 m) to a required lux level. It is mainly determined by pole height, lumen output and beam optics, which together control how wide, bright and uniform the lighting will be.

High mast lighting systems are designed to illuminate large outdoor areas such as highways, ports, logistics yards and industrial sites—where safety depends on uniform visibility, not just “a bright circle under each pole”.

The high mast lighting coverage area is the ground area that is illuminated to a usable lux level (for example 20–30 lux for ports and yards) by fixtures mounted on tall poles, typically 20–45 m high. It depends mainly on mounting height, lumen output and optical design (beam angle / distribution).

If you are an EPC contractor or municipal engineer, getting this wrong can mean dark patches, glare complaints or failing the final inspection. This guide focuses on the practical relationship between height, optics and real-world coverage—and how to optimize your high mast light pole design for maximum efficiency.

What Determines High Mast Lighting Coverage Area?

In practice, the effective coverage area of a high mast system is controlled by three factors working together:

-

Mounting height

Higher poles naturally spread light over a wider area, but the lux level on the ground drops as distance increases. -

Lumen output

Higher wattage and more efficient LEDs (lm/W) allow you to maintain the required lux over a larger surface. -

Beam optics (the most critical factor)

Even at the same height and wattage, different lenses create very different coverage patterns:- Narrow beam (15–30°) – pushes light far with high intensity, suitable for very tall poles or focused zones.

- Medium beam (30–60°) – balances distance and spread, common in many high mast projects.

- Wide or asymmetric optics (Type III / IV / V) – shape the light to cover rectangular yards, road junctions or container fields with good uniformity.

When we talk about high mast lighting coverage area, we are not just asking “how big is the circle on the ground?”, but “how big is the area where lux and uniformity still meet the project requirements?”

How Pole Height Affects Coverage

Raising the pole height creates a very clear trade-off:

- Coverage area increases – the light cone widens, so one mast can reach further.

- Ground illuminance decreases – according to the inverse square law, if you double the distance from the light source, the illuminance falls to roughly one quarter.

From field projects, the pattern is:

- At 20 m, you get relatively high lux and tighter coverage—good for focused areas like small plazas or industrial yard sections.

- At 30–35 m, one pole can cover much more ground, which reduces the number of foundations and masts—but you must increase wattage and use proper optics to avoid dim zones.

In a recent port upgrade in East Africa, switching from 25 m to 35 m masts allowed us to reduce the number of poles by about 40%. However, we needed to move from 600 W to 900 W LED modules and use asymmetric optics to keep average lux and uniformity within the specification. Height and power must always be tuned together.

Quick Reference: Estimated Coverage by Pole Height

The table below gives rough guidance on coverage for typical high mast systems using asymmetric LED floodlights on multi-arm heads.

Note: Values assume several fixtures per mast, with overlapping Type IV/Type V optics and proper aiming. They are for early planning only—final designs should always be based on photometric simulation.

| Pole Height (m) | Typical Coverage Diameter (m) | Typical Application | Recommended LED Power per Mast (Approx.) |

|---|---|---|---|

| 20 m | 60–80 m | Small yards, toll plazas, roundabouts | 400–600 W |

| 25 m | 80–100 m | Highway interchanges, medium yards | 600–800 W |

| 30 m | 100–130 m | Large industrial yards, depot areas | 800–1,000 W |

| 35 m+ | 130–160 m+ | Ports, container terminals, large aprons | 1,000–1,500 W |

These ranges are based on typical layouts we see in ports, logistics parks and industrial zones. For critical tasks (crane operation, aircraft apron, TV broadcast), lux and uniformity requirements are higher and need more detailed design.

Why Beam Optics Matter More Than Height Alone

Many projects fail not because the pole height is wrong, but because the optics are wrong for the application.

At the same 30 m height, you can have:

- A narrow 30° floodlight that creates a bright hotspot and very dark surroundings.

- A wide asymmetric Type IV floodlight that spreads light across a container yard with good uniformity.

- A Type V circular distribution suitable for open paved areas or large car parks.

Good high mast light pole design is really about using the right optics and aiming so that the beams overlap correctly on the ground. This is why a simple chart or rule-of-thumb is not enough for serious projects.

How to Estimate Coverage – And Why Hand Calculations Are Not Enough

Designers sometimes use a simple trigonometric relation to estimate the coverage of a single fixture:

📐 Rule-of-Thumb Coverage Calculation

Coverage Radius (R) ≈ Mounting Height (H) × tan(Beam Angle / 2)

Example:

- Height = 30 m

- Beam Angle = 60°

- Radius ≈ 30 × tan(30°) ≈ 17.3 m

- Coverage Diameter ≈ 34.6 m per fixture

This calculation is useful to understand the geometry of the beam, but it has serious limitations for real projects:

-

It ignores uniformity

You might achieve high lux directly under the pole and almost nothing at the edges. -

It ignores overlapping beams

On real high mast heads, you have 3–12 fixtures with different orientations. The useful coverage is created by their combined pattern, not a single cone. -

It ignores obstructions and reflectance

Containers, cranes, buildings, road surfaces and ground reflectance will all affect the final lighting result.

Because of these factors, hand calculations are good for conceptual understanding, but not for final design.

The Professional Way: Use DIALux / Relux Simulation

For ports, highways and industrial sites, clients and authorities usually specify:

- Average illuminance (Eav) on the working plane

- Minimum illuminance (Emin) and uniformity (U₀ = Emin / Eav)

- Sometimes glare limits and obtrusive light (spill light) limits

You can only check these reliably with proper lighting design software such as DIALux or Relux, using the luminaire’s IES/LDT photometric files.

If you share a simple site sketch or CAD (DWG) drawing with pole positions, our engineering team can generate a photometric report showing average lux, uniformity and suggested mast height for your application.

🛑 Don't Risk Dark Spots in Your Project

Hand calculations can’t predict shadows from containers, cranes or buildings.

Send us your AutoCAD (DWG) site plan or even a simple hand sketch with dimensions.Our lighting engineers will run a full DIALux simulation to verify lux levels and uniformity before you order a single pole or fixture.

Recommended Pole Heights by Application

Different applications call for different compromises between height, coverage and glare control.

| Application | Typical Height Range (m) | Design Focus |

|---|---|---|

| Highway interchanges | 25–30 m | Driver comfort, reduced glare, wide junction coverage |

| Toll plazas & roundabouts | 20–25 m | Compact coverage, high vertical illuminance |

| Industrial yards | 25–30 m | Safe movement of trucks and forklifts |

| Container terminals | 30–40 m | Long-range coverage over stacked containers |

| Port berths & aprons | 30–45 m | Minimize shadows near cranes and loading edges |

| Stadium perimeters / large car parks | 25–35 m | Uniformity and CCTV visibility |

In many African industrial parks we see 25–30 m as the sweet spot between cost and performance. Taller poles (35–40 m) are usually reserved for container yards, port terminals or large logistics hubs where each mast must cover a huge area.

Factors That Reduce Real Coverage Area

Even with the “correct” height, several practical issues can shrink your effective coverage:

-

Wrong beam angle

Using overly narrow optics in a wide yard, or wide optics where forward-throw distribution is needed. -

Poor pole spacing

Poles placed too far apart create “zebra striping”: bright under the mast, dark in between. -

Obstructions

Stacked containers, large machinery, or buildings can block part of the beam and create unexpected shadows. -

Maintenance factor

Over time, dust, humidity and LED lumen depreciation reduce output. Good design includes a maintenance factor (e.g. 0.8) so the system still meets lux after several years. -

Dirty or aged optics

Unclean lenses or yellowed covers can cut effective lumen output and reduce practical coverage by 10–20%.

Good projects anticipate these factors during the design phase instead of discovering them after installation.

Best Practices for Maximizing High Mast Lighting Coverage Area

To get the best performance from each mast:

-

Select application-specific optics

Use asymmetric Type III/IV distributions for roads and yards, and Type V for open, circular areas. -

Simulate before ordering

Run DIALux or Relux simulations with actual IES files and site layout instead of relying on generic charts. -

Balance height, power and pole count

Sometimes adding one more mast at a slightly lower height is cheaper and safer than forcing a few very tall masts to “do everything”. -

Design for uniformity, not just average lux

A yard with 25 lux average but terrible uniformity feels darker and less safe than a 15–18 lux yard with excellent uniformity. -

Include maintenance in your design thinking

Account for dirt, aging and access: high masts in dusty environments will need periodic cleaning and inspection. -

Coordinate with civil and electrical teams

Foundation design, earthing, cable routing and access for cherry pickers or lowering systems are all part of a successful high mast lighting project.

Conclusion: From Coverage Guesswork to Engineered Results

Designing a high mast lighting coverage area is more than picking a pole height from a table. It is about matching:

- The right height

- The right optics and lumen package

- The right pole spacing and layout

so that your port, logistics yard or highway interchange meets its safety and operational requirements with controlled cost.

If you are simply checking what “20 m vs 30 m” means in theory, the charts in this guide are a good starting point. But for real projects—especially those that will operate for 10–20 years—it is worth turning those ideas into a proper high mast light pole design backed by simulation.

If you would like support with that: