For most roadway lighting projects, SMD luminaires are preferred because they offer more flexible optical distributions and simpler maintenance. COB can be a strong option for long-throw or high-mount applications when the optical design and thermal path are properly engineered. The decision should be made at the luminaire level (optics, thermal design, and maintenance strategy), not by LED package claims alone.

Rule of thumb: Choose SMD for wide-road uniformity and modular maintenance; choose COB when higher center intensity and controlled long throw are required.

At a glance:

- SMD → better uniformity on wide roads + modular maintenance

- COB → higher center intensity for long throw + tighter beam control

2-Minute Self-Check: Are You Closer to SMD or COB?

Answer these 3 questions and you’ll know the right direction:

- Is your road primarily wide (multi-lane uniformity) or does it require long throw (large spacing / higher mounting)?

- What are your pole height and pole spacing (e.g., 10–12 m, 35–40 m)?

- Do you prioritize uniformity + maintenance simplicity, or forward throw + center intensity?

If you want, send these 3 inputs to our engineering team and we’ll reply with a practical engineering direction: SMD vs COB + optics direction + a typical wattage range.

Choosing between SMD and COB LED street lights is one of the most common—and most misunderstood—decisions in roadway lighting projects.

Many comparisons focus on chip efficacy, lumen numbers, or package size, but in real street-lighting applications, these metrics alone rarely determine on-road performance. What ultimately matters is how the entire luminaire system performs after optics, thermal limits, drivers, and maintenance realities are accounted for.

This guide explains the real engineering differences between SMD and COB for street lighting, clears up common misconceptions, and shows you how to choose the right solution based on road geometry, optics, and lifecycle considerations, not marketing claims.

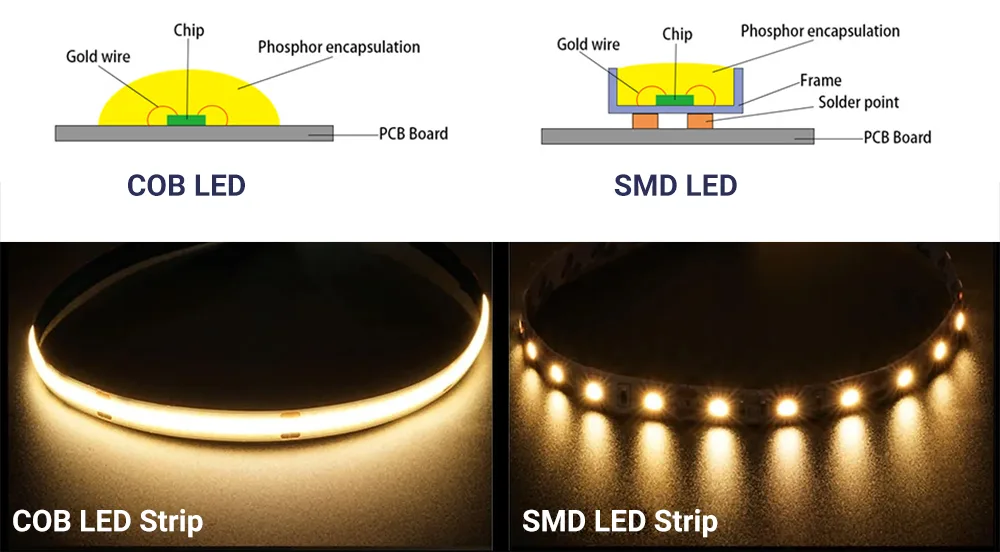

What Is SMD in Street Lighting?

SMD (Surface-Mounted Device) street lights use multiple LED packages mounted across a PCB, combined with secondary optical lenses to shape the light distribution.

Typical characteristics:

- Modular LED layout

- Flexible optical distributions (Type II, Type III, Type IV, etc.)

- Better lateral heat spreading across a larger surface

- Easier replacement and standardized maintenance

SMD designs are widely used in municipal roads, highways, and urban arterials, where uniformity, scalability, and long-term serviceability are critical.

What Is COB in Street Lighting?

COB (Chip-on-Board) street lights integrate many LED dies into a single light-emitting surface.

Typical characteristics:

- Higher central luminance density

- Compact light source area

- Strong forward throw when paired with narrow or forward optics

- Higher thermal density at the source level

COB solutions are often selected for applications requiring long throw, higher mounting heights, or focused beam control, provided thermal design is properly managed.

Common Misconceptions About SMD vs COB

Many debates around SMD vs COB arise from mixing LED-package-level metrics with luminaire-level performance. In roadway lighting, this leads to incorrect conclusions.

Below are the most common misconceptions and what actually matters.

SMD vs COB Efficiency: Why Chip lm/W Can Be Misleading

SMD LED packages often show high lm/W under laboratory conditions. However, street-light efficiency must be evaluated at the luminaire level, not the chip level.

Key factors that affect real efficiency:

- Optical losses from lenses, covers, and cutoff geometry

- Driver efficiency and current regulation

- Thermal behavior under outdoor ambient temperatures

- How much light actually reaches the road surface (optical utilization)

Definition you should remember:

LED package efficacy is lm/W measured at the LED package. Luminaire efficacy is lm/W measured at the complete luminaire output after optics, housing, and driver losses. Road performance depends far more on luminaire efficacy plus optical utilization than on package numbers alone.

A luminaire with slightly lower package efficacy can still deliver higher usable road illuminance if its optics and thermal design are superior.

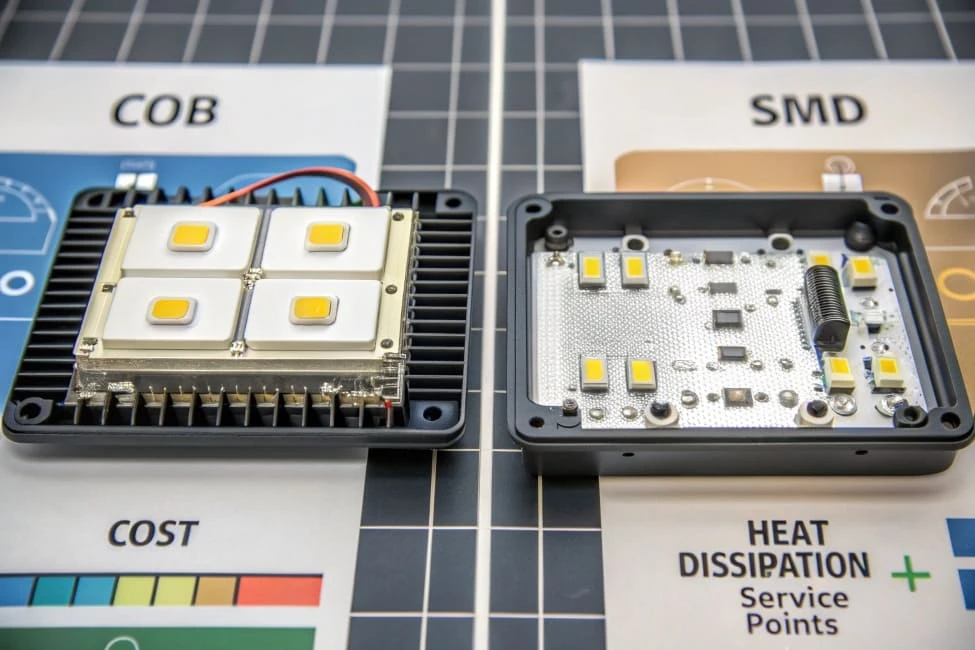

COB Heat Dissipation: What’s Solvable and What Usually Fails

COB concentrates heat into a smaller area, which makes thermal design more critical, but not inherently unreliable.

COB thermal performance depends on:

- Substrate conductivity and interface quality

- Heatsink size and airflow design

- Drive current limits

- Ambient temperature assumptions

Most COB failures are not caused by the package itself, but by:

- Overdriving to chase lumen numbers

- Inadequate thermal interfaces

- Undersized housings

With proper engineering, COB street lights can operate reliably even in demanding environments.

Chip Count Myths: Why Optics Matter More Than “More LEDs”

A higher chip count does not automatically produce better road lighting.

Common issues in chip-heavy designs:

- Excessive overlap wasting lumens

- Increased driver complexity

- More potential failure points

- Poor utilization of emitted light

In roadway lighting, performance is determined by:

- Beam pattern and optical distribution (e.g., IES Type II / III / IV)

- Mounting height and pole spacing

- Road width and geometry

This is why beam pattern and optical efficiency matter more than raw chip count.

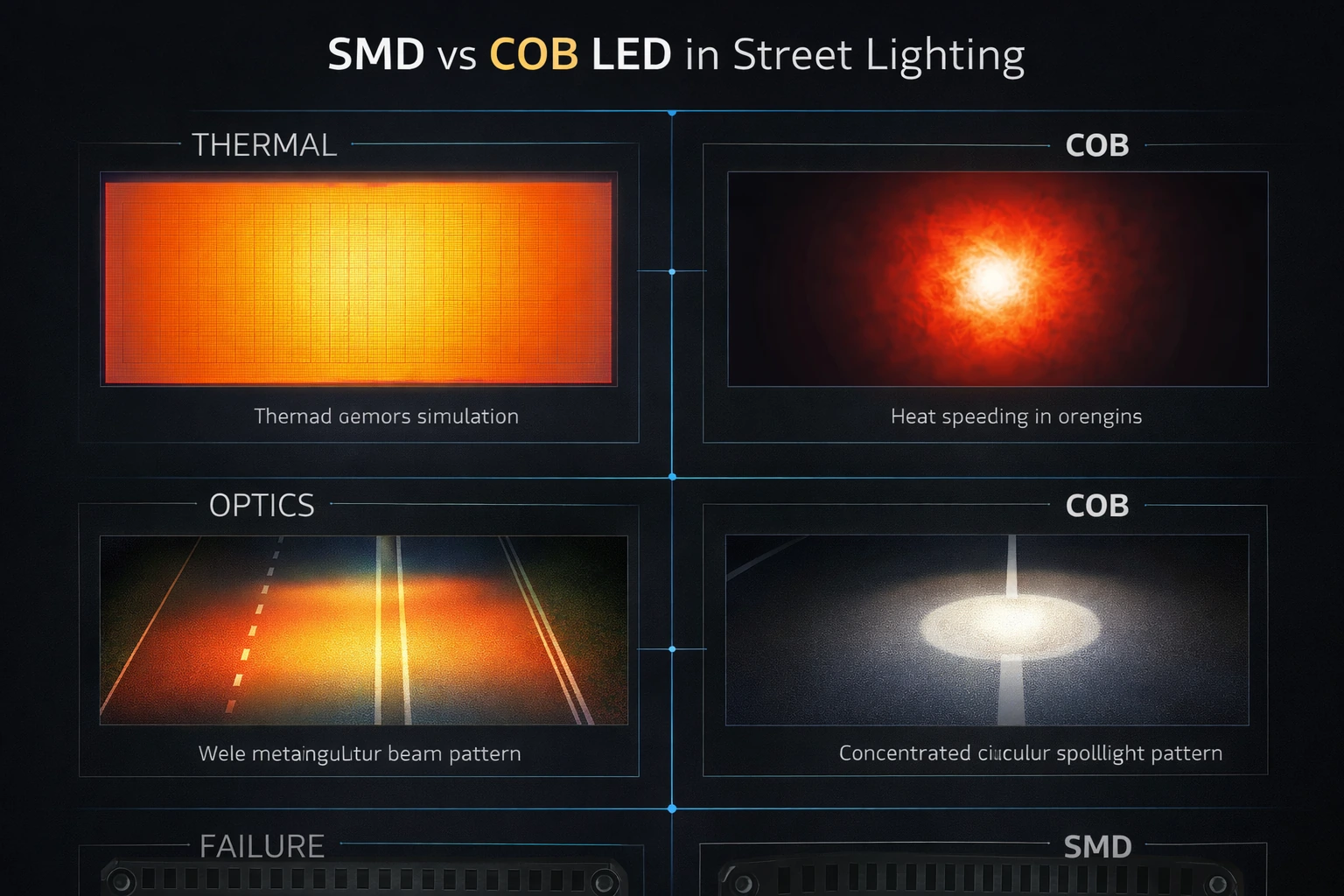

Which Is Better for Street Lights?

The honest engineering answer is that it depends on the application.

In practice:

- SMD excels in wide roads and multi-lane coverage where uniformity is critical

- COB performs well in long-throw or high-mount scenarios requiring focused intensity

- Glare control depends primarily on optical design and cutoff, not on whether the LED is SMD or COB

The LED package alone does not determine success. The entire luminaire system does.

Download the 1-Page Decision Sheet (PDF)

If you want a one-page summary you can forward to your team or use in tender discussions, prepare a PDF that includes: the selection logic by road conditions, the evidence to request (LM-79 / IES), and the most common red flags.

Suggested button text:

What to Request From Suppliers

Before comparing SMD vs COB, request:

- LM-79 photometric test report (luminaire-level performance)

- IES photometric file (beam pattern and distribution)

- Optical type or distribution confirmation (Type II / Type III / Type IV or project-specific)

- Drive current and thermal design assumptions

- Warranty terms and maintenance/spare strategy

If these are missing, treat “high lumen” or “ultra-long lifetime” claims as unverified.

Free: Supplier Red-Flag Checklist + Copy-Paste Email Template

Many EPC and procurement teams don’t fail because they chose SMD or COB. They fail because they accept exaggerated specs without test evidence.

Offer two simple tools:

- Supplier Red-Flag Checklist (LM-79 / IES / Warranty)

- Copy-Paste Email Template (Request LM-79 + IES)

Here is a copy-paste email template you can send to any supplier:

Subject: Request LM-79 Report and IES File for Roadway Evaluation

Hi [Name],

Please share the following for the street light model [Model]:

- LM-79 photometric test report (full report)

- IES photometric file

- Optical distribution type (Type II / Type III / Type IV or project-specific)

- Drive current and thermal assumptions (ambient temperature, housing temperature limits)

- Warranty terms and spare/maintenance strategy

We will use these to validate road performance (uniformity, glare control, and long-term stability).

Thanks,

[Your Name]

Quick Engineering Decision Guide: SMD or COB

| Project Requirement | Recommended Direction | Engineering Reason |

|---|---|---|

| Wide roads, multi-lane coverage | SMD | Better lateral distribution and optical flexibility |

| Long pole spacing / long throw | COB | Higher center intensity with focused beam control |

| Maintenance priority | SMD | Modular boards and standardized replacements |

| Glare-sensitive areas | Depends on optics | Glare is an optical and geometric issue |

| Lifecycle cost optimization | Case dependent | Optical efficiency and maintenance dominate long-term cost |

Note: This table summarizes typical tendencies, not absolute rules. Final selection should be validated by photometry (IES/LM-79), road geometry, and thermal limits.

FAQ

Is COB brighter than SMD?

Not inherently. COB can produce higher intensity from a smaller source, but actual road brightness depends on optics, mounting height, and beam distribution.

Is SMD more efficient than COB?

Sometimes, but not always. Real efficiency depends on luminaire design, thermal behavior, optical losses, and driver efficiency, not just LED package efficacy.

Which is better for street lights?

In most municipal projects, SMD is preferred for its distribution flexibility and maintainability. COB performs well in specific long-throw or high-mount applications when properly engineered.

Which has better heat dissipation?

SMD is generally more forgiving due to distributed heat. However, a well-designed COB thermal path can also be reliable under controlled drive conditions.

Which is easier to maintain?

Typically SMD luminaires, as modular LED boards allow simpler replacement and spare standardization.

Do COB street lights cause more glare?

No. Glare depends on optical cutoff, beam control, mounting geometry, and applicable standards, not on the LED package type.

Can SMD and COB be used in the same project?

Yes. Some projects use SMD for main road sections and COB for intersections or long-throw zones, provided optics and maintenance planning are consistent.

Get a Project-Specific Engineering Recommendation

Not sure whether SMD or COB is right for your road?

If you share:

- Road width and lane count

- Pole height and spacing

- Target average illuminance or uniformity requirement

Our engineering team can provide:

- SMD vs COB recommendation

- Suggested wattage range

- Typical IES distribution options

- Maintenance-oriented configuration advice

No marketing brochure. No exaggerated claims. Only engineering logic based on real roadway performance.

Request an engineering-based recommendation for your project.