Need to choose the right lighting pole but feel overwhelmed by all the options? Let me break it down for you.

There are many types of lighting poles, each serving specific applications—from highways to parks, from steel to solar. Choosing the right type can greatly impact performance, cost, and safety.

Picking the right pole isn't just about looks. It affects everything: safety, efficiency, and long-term cost. Let's walk through the key types and their uses.

What are lighting poles?

A new infrastructure project can stall without good lighting. But what makes a good lighting pole?

Lighting poles are vertical supports used to hold light fixtures. They are critical in public infrastructure and private property illumination.

They keep lights elevated to ensure proper coverage and visibility. But not all poles are created equal. Their function and performance vary based on material, design, and location.

Why choosing the right type matters

Proper pole selection means fewer maintenance issues, better lighting quality, and improved safety. Choosing the wrong type? That means premature failures, safety risks, and wasted money.

Overview of common applications

Lighting poles serve multiple sectors:

- Roads and Highways: For visibility and safety.

- Parks and Pathways: For ambiance and pedestrian safety.

- Commercial Areas: For functionality and branding.

- Remote Locations: For sustainability and off-grid power.

Steel Lighting Poles: Applications and Advantages?

Need high durability and maximum load capacity? Steel poles might be your best bet.

Steel poles are strong, reliable, and highly durable. They are preferred for roads, highways, and industrial areas.

Dive deeper: Why steel works best for heavy-duty areas

Steel lighting poles are the go-to for high-traffic areas. Their robustness allows them to carry heavier fixtures and resist high wind loads.

Advantages of steel poles:

- High load capacity

- Long lifespan with galvanization or powder coating

- Customizable heights and shapes

- Excellent wind resistance

Applications:

- Highways: Where reliability and long-span lighting are essential.

- Industrial Zones: Need for strong support due to large fixtures.

- Airports and Ports: Areas exposed to harsh weather and constant use.

But steel poles need proper corrosion protection. In coastal or high-humidity areas, regular maintenance or advanced coatings like HDG (Hot-Dip Galvanization) are necessary.

| Feature | Steel Poles |

|---|---|

| Strength | High |

| Corrosion Resistance | Medium (requires coating) |

| Weight | Heavy |

| Applications | Highways, factories, airports |

Aluminum Lighting Poles: Lightweight and Corrosion-Resistant?

Worried about rust or need something easier to install? Aluminum poles offer a sleek, corrosion-free solution.

Aluminum poles are lightweight and naturally corrosion-resistant, making them ideal for coastal regions, parks, and pedestrian pathways.

Dive deeper: Where aluminum shines

Aluminum doesn’t rust. That makes it perfect for locations with high humidity, rainfall, or salt exposure.

Key benefits:

- Easy to transport and install

- Minimal maintenance required

- Stylish appearance (often anodized or powder coated)

- Environmentally friendly—100% recyclable

Ideal environments:

- Coastal Towns: Salt resistance is critical.

- Public Parks: Aesthetic appeal matters.

- Residential Zones: Quiet areas needing subtle designs.

They’re less strong than steel but good enough for medium loads.

| Feature | Aluminum Poles |

|---|---|

| Strength | Moderate |

| Corrosion Resistance | High (natural oxide layer) |

| Weight | Light |

| Applications | Parks, coastlines, urban areas |

Concrete Lighting Poles: Stability for Harsh Environments?

Need a lighting pole that lasts decades, even in extreme environments? Concrete might be your solution.

Concrete poles are durable and stable. They are widely used in urban roads and highways where vibration resistance is important.

Dive deeper: Concrete for endurance

These poles are cast from reinforced concrete. They can resist:

- High winds

- Vibrations from nearby roads

- Fire and chemical exposure

Their heavy weight makes them hard to install, but once in place, they’re rock solid.

Key Advantages:

- Long service life

- Great for fixed, non-temporary installations

- Minimal vibration

- Low maintenance

Common Applications:

- City Roads

- Bridge Approaches

- Windy Areas

| Feature | Concrete Poles |

|---|---|

| Strength | High |

| Corrosion Resistance | High |

| Weight | Very Heavy |

| Applications | Roads, bridges, highways |

Fiberglass and Composite Lighting Poles: Modern Lightweight Solutions?

Looking for a rust-free, non-conductive option? Fiberglass poles are a smart, modern choice.

Fiberglass and composite poles are engineered for lightweight applications. They’re great in areas where weight, insulation, or rust are concerns.

Dive deeper: High performance with low impact

Fiberglass poles offer unique advantages:

- They don’t conduct electricity—ideal near power lines.

- They’re rustproof.

- They are easy to handle and transport.

But they have limited load capacity, making them suitable only for certain types of lights.

Best Use Cases:

- School Campuses

- Historical Sites

- Wetlands and Coastal Walkways

| Feature | Fiberglass Poles |

|---|---|

| Strength | Low to Medium |

| Corrosion Resistance | Excellent |

| Weight | Very Light |

| Applications | Decorative, low-power zones |

Single Arm and Double Arm Lighting Poles?

Want to balance light over wide roads or narrow lanes? Design matters.

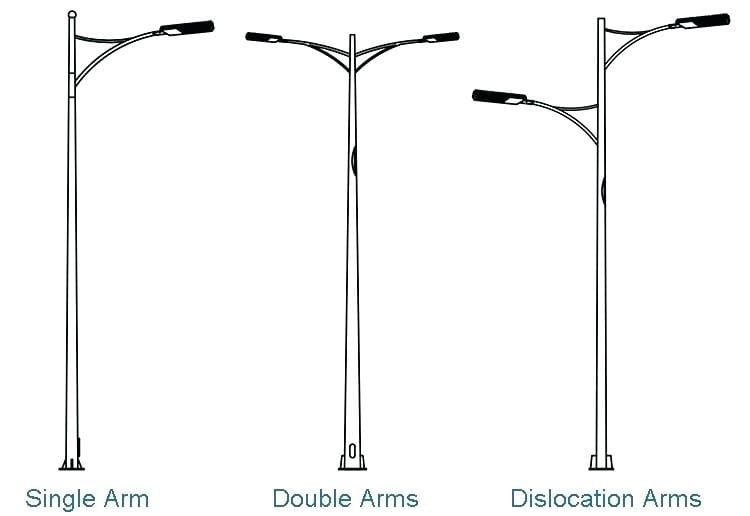

Single arm poles light one side, while double arm poles can illuminate both sides of a road.

Dive deeper: Form meets function

- Single Arm: Used for pedestrian paths or narrow roads.

- Double Arm: Ideal for central medians in dual-lane roads.

Double arms reduce the number of poles needed and give symmetrical lighting.

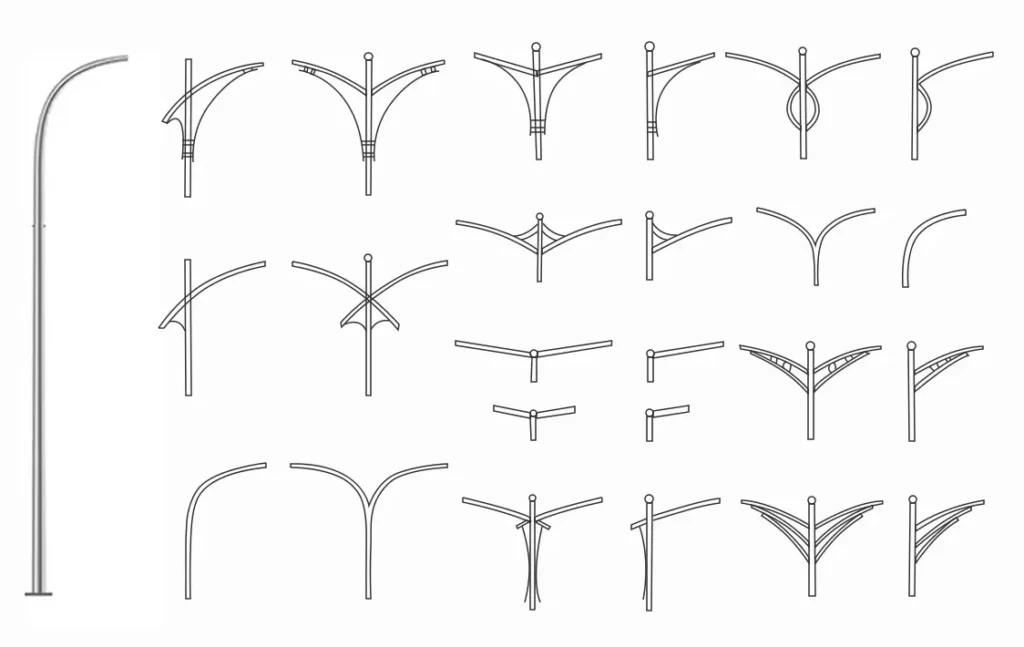

Decorative Lighting Poles for Urban and Landscape Use?

Need to match the charm of a historic district? Go decorative.

Decorative poles blend aesthetics and functionality. They are common in parks, plazas, and scenic routes.

Dive deeper: Making a statement

Styles range from vintage cast-iron to modern curves in fiberglass or aluminum.

These poles often feature:

- Ornate bases and arms

- Integrated banner arms or planters

- Warm light temperatures

They contribute to a place’s visual identity.

High Mast Lighting Poles for Large Area Illumination?

Need to light up a stadium or airport with fewer poles? Go high.

High mast poles are tall structures with multiple fixtures at the top, used in large open areas.

Dive deeper: Less is more

They reduce the number of poles needed while providing high-lumen coverage.

Used in:

- Airports

- Stadiums

- Intersections and ports

These poles require cranes for maintenance.

Solar Lighting Poles: Sustainable and Off-Grid Applications?

No grid? No problem. Solar lighting poles bring power anywhere.

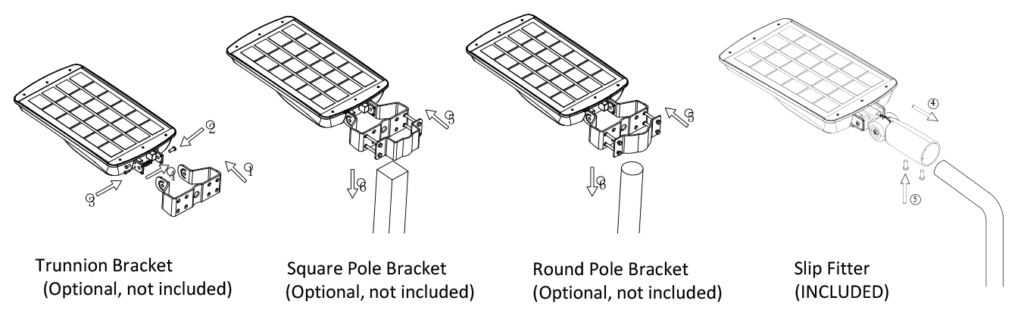

Solar poles have built-in PV panels, batteries, and controllers. They work in rural or disaster-prone areas where grid power fails.

Dive deeper: Lighting the future

Types of systems:

- All-in-one: Compact, simple install

- Split-type: Higher capacity, more flexible

Great for:

- Villages

- Refugee camps

- Parks and eco-parks

They reduce electricity bills and carbon emissions.

Choosing the Right Lighting Pole for Your Application?

Lost in choices? Focus on the basics: location, weather, height, and load.

Dive deeper: The checklist

Ask these:

- Will it face salt or moisture?

- How heavy is the light fixture?

- Is there wind or snow load?

Other key points:

- Aesthetics for public spaces

- Conductivity if near utilities

- Local regulations and certifications

Installation and Maintenance Considerations for Lighting Poles?

Don't forget: poles are only as good as their foundation.

Dive deeper: Long-term thinking

Common foundations:

- Direct burial

- Flange-mounted with anchor bolts

Maintenance:

- Inspect every 6–12 months

- Check for rust, cracks, or leaning

- Replace bolts and fixtures as needed

Initial cost is just part of the story. Long-term performance matters more.

Comparison Table of Lighting Pole Types

| Material | Strength | Weight | Rust-Resistance | Common Use Case |

|---|---|---|---|---|

| Steel | High | Heavy | Medium | Highways, industrial areas |

| Aluminum | Medium | Light | High | Parks, coastlines |

| Concrete | High | Very Heavy | High | Urban roads, bridges |

| Fiberglass | Low | Very Light | Excellent | Decor, low-impact environments |

| Wood | Medium | Medium | Medium | Rural, aesthetic areas |

Frequently Asked Questions About Lighting Poles

What is the standard height for street lighting poles?

Typically between 6 to 12 meters, depending on road width.

Which material lasts the longest?

Concrete and galvanized steel offer the longest lifespans.

Are solar lighting poles effective in cloudy regions?

Yes. As long as they’re sized correctly, they can store enough energy even during cloudy days.

Conclusion

Choosing the right lighting pole depends on many factors—material, environment, usage, and aesthetics. Make sure you evaluate all options or talk to a professional before buying.