A light pole foundation is a reinforced concrete structure that transfers a pole’s vertical load and wind-induced lateral loads into the soil, preventing overturning, excessive deflection, and long-term leaning. Final sizing depends on pole height, wind speed/terrain category, soil bearing capacity, and local codes (IBC/AASHTO/EN or local standards). For most 8–15 m projects, a spread footing with anchor bolts + base plate is the most practical and maintainable solution.

Rule of thumb (early estimation only): For direct-burial poles, embedment depth is often estimated as ≈ 10% of pole height + 600 mm (2 ft), but final design must be verified by a qualified structural engineer.

💡 Don’t want to struggle with this alone?

Sunlurio can support EPC and municipal projects with poles, HDG anchor bolt kits (with steel templates), and typical foundation suggestions.

👉 Send Your Pole Schedule for a Free Review

What Is a Light Pole Foundation?

A light pole foundation is a structural system designed to resist:

- Overturning (wind moment at the base)

- Sliding (lateral shear at ground level)

- Soil bearing pressure (compression/uplift zones)

- Long-term movement (settlement, groundwater effects, repeated wind cycles)

It’s the “hidden structure” that decides whether your poles stay straight for 10–20 years.

1. Why Light Pole Foundations Fail More Often Than LEDs

On most street and area lighting projects, teams focus on:

- pole height and spacing

- lumen output and fixture efficiency

- fixture brand and optical distribution

Years later, when something goes wrong, it’s rarely the LED. Most serious issues are related to foundations and anchor bolts:

- poles start to lean after several rainy seasons

- concrete around the base plate cracks or breaks away

- anchor bolts corrode or loosen, especially near the grout level

- auditors ask an uncomfortable question:

“Where is your foundation design and structural calculation?”

This guide is for municipal engineers, EPC contractors, project managers and distributors working with grid-powered LED street lights and poles.

2. Design Objectives: Safety, Compliance and Lifetime Cost

A good foundation should:

-

Keep the pole vertical and stable

- under daily wind, temperature changes and soil movement

- during occasional extreme events

-

Meet local codes and standards

- building codes (often based on IBC, AASHTO, EN standards)

- defined safety factors for overturning, sliding and soil bearing

-

Be buildable and repeatable

- simple enough for local contractors to follow

- easy to inspect and sign off

-

Control lifetime cost

- slightly larger footing and proper corrosion protection at the start

- usually save many site visits, emergency repairs and complaints later

For infrastructure projects with long service life requirements, hot-dip galvanized street light poles are commonly specified due to their corrosion resistance, structural reliability, and predictable lifetime performance.

3. Design Inputs Engineers Actually Use

Typical inputs for light pole foundation design include:

3.1 Pole & luminaire data

- pole height, arm length, number of arms

- weight and projected area of luminaires

- extra equipment (signage, CCTV, speakers, banners, etc.)

3.2 Wind load data

- basic wind speed from local code (e.g., 30–50 m/s)

- terrain category (open field, coastal, suburban, urban)

- importance factor for critical facilities (main roads, airports, ports)

3.3 Soil conditions

- soil type (rock, dense sand, clay, fill)

- allowable bearing capacity

- frost depth and groundwater level

3.4 Project requirements

- service life expectations

- limitations on top-of-pole deflection or vibration

- local client or municipal specifications

4. Simplified Structural Logic (IBC / AASHTO Style)

Most modern codes follow a similar workflow:

- Model the pole as a cantilever fixed at ground level.

- Calculate the horizontal wind force V on the pole and fixtures.

- Compute the bending moment M and shear at the foundation top.

- Select foundation size and embedment depth so that:

- soil pressure is ≤ allowable bearing capacity

- overturning and sliding safety factors are satisfied

⚠️ Important

Exact formulas depend on the code and soil model. Final foundation design must always be checked and approved by a qualified structural engineer under local regulations.

As a manufacturer, Sunlurio provides realistic loads, typical foundation solutions and structural data to support your engineering team.

5. Common Types of Street Light Pole Foundations

There is no single “best” foundation type. The right choice depends on pole height, soil conditions, environment and budget.

5.1 Direct-embed concrete foundation

- pole or stub post embedded directly into a concrete footing

- simple and economical for lower poles (≤ 6–8 m) in good soil

- often used in small car parks, minor roads and pathways

Pros

- low material and fabrication cost

- straightforward construction

Cons

- not ideal for higher poles or poor soils

- changing poles later is more difficult

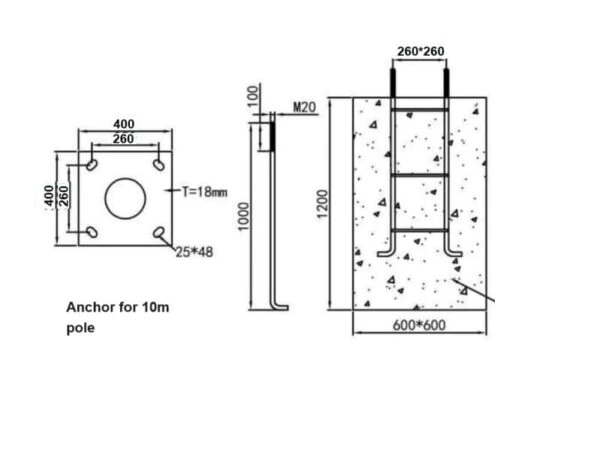

5.2 Spread footing with anchor bolts (most common for 8–15 m)

- reinforced square or round concrete footing

- pole connected using a base plate and anchor bolts

- most common choice for municipal and industrial projects

Pros

- easy to install and align poles

- easy to inspect anchor bolts and grout

- easier to replace poles in the future

Cons

- requires accurate placement of anchor bolts and conduits

- concrete quality and grouting need supervision

5.3 Pile or drilled shaft foundations

- used in weak or highly variable soils, floodplains or near water

- pole attached to a pile cap or reinforced shaft

Pros

- higher capacity in difficult ground conditions

- better long-term performance in flood or coastal environments

Cons

- more expensive and time-consuming

- requires specialized equipment and experienced contractors

📝 Sunlurio practical note

For most municipal and industrial projects with 8–15 m poles, a reinforced spread footing with anchor bolts usually gives the best balance of safety, cost and maintenance convenience.

6. Typical Foundation Sizes (Engineering Ranges)

These are typical ranges only. Final sizing depends on wind zone, soil bearing capacity, pole configuration and local code checks.

| Pole Height | Common Foundation Type | Typical Footing Size Range (W×W×D) | Notes |

|---|---|---|---|

| 6–8 m | Direct embed / spread footing | 600×600×900 to 800×800×1200 mm | Depends heavily on soil + wind |

| 9–10 m | Spread footing + anchor bolts | 800×800×1200 to 1000×1000×1500 mm | Common municipal range |

| 11–12 m | Spread footing + anchor bolts | 1000×1000×1500 to 1200×1200×1800 mm | Higher wind zones push sizes up |

| 14–15 m | Spread footing / pile (site dependent) | 1200×1200×1800 mm and above | Consider piles in weak soils |

7. Anchor Bolts & Base Plates – Where Many Projects Go Wrong

A typical light pole base connection includes:

- 4–8 anchor bolts arranged on a bolt circle

- a base plate welded to the pole shaft

- leveling nuts and top nuts for alignment and clamping

- a non-shrink grout layer between base plate and concrete

- a rebar cage tying bolts into the footing

7.1 Anchor bolt best practices (easy to audit)

- choose bolt diameter and number based on bending moment and shear

- provide sufficient embedment length (hooked / headed bolts if required)

- maintain spacing and edge distance per code

- specify hot-dip galvanized (HDG) anchor bolts (e.g., ASTM A153 or EN ISO 1461)

- protect the critical zone at and above the grout line against standing water

7.2 Never pour concrete without a rigid template

Loose anchor bolts move during casting. The result is simple and painful: the base plate holes don’t fit, and the pole cannot be installed.

At Sunlurio, anchor bolt kits can include a matched steel positioning template, helping contractors keep bolts aligned and vertical during concrete pouring.

8. Grouting & Leveling (Small Detail, Big Consequences)

Most long-term complaints start here:

- missing grout or hollow grout zones under the base plate

- voids allow water to sit → corrosion and loosening

- alignment drifts under wind cycles and vibration

Good practice

- level using leveling nuts

- fully pack non-shrink grout under the plate

- inspect for voids before sign-off

9. Cabling & Trenching (Grid-Powered Pain Point)

Unlike solar street lights, grid-powered systems require trenches and cables. Many site problems come from poor coordination between civil works and electrical works.

9.1 Conduit location and size

- conduit must align with the pole handhole

- avoid sharp bends that make pulling cables difficult

- select appropriate diameter/material per local electrical code

9.2 Entry into the foundation

- plan conduit entry positions in advance

- use sleeves or formed openings to reduce cracking risk

- seal around conduits to reduce water ingress into handholes

9.3 Trench depth and backfilling

- follow code requirements for minimum burial depth

- backfill and compact correctly to reduce settlement

- coordinate with other underground utilities (water, gas, telecom)

📌 Practical tip

Combine foundation + conduit entry + pole handhole in one drawing to reduce rework and change orders.

10. Step-by-Step Workflow for EPC Teams

-

Collect project data

- pole heights, arm configurations, luminaire types

- site location, wind zone, terrain category

- soil report (if available) or typical soil assumptions

-

Define design criteria

- service life and maintenance philosophy

- applicable design code (IBC/AASHTO/EN/local)

- safety factors and allowable deflection limits

-

Calculate loads

- wind pressure at relevant height

- projected area of pole + luminaires + accessories

- base moment M and shear V

-

Select foundation type and size

- direct-embed vs spread footing vs pile/shaft

- check bearing, overturning, sliding

-

Design anchor bolts and base plate

- bolt circle, diameter, quantity

- base plate thickness/weld details

- HDG protection + grout detail

-

Detail cabling and trenches

- conduit entry, route, depth and earthing

- align conduits with handholes and junction boxes

-

Prepare drawings and calculation summary

- plan + section views

- base plate & bolt detail

- short calculation note for approval/audit

11. Installation & Inspection Checklist (Site Sign-Off)

Foundation & concrete

- dimensions match drawings

- rebar cage location and cover correct

- concrete grade meets spec (commonly 3000–4000 PSI; confirm local requirement)

- concrete properly vibrated (no major honeycombing)

Anchor bolts

- rigid template used during casting

- bolts straight, correct projection above concrete

- bolt circle matches base plate holes

Grouting & leveling

- pole aligned with leveling nuts

- non-shrink grout fully fills under the base plate

- no large voids or hollow grout zones

Cabling

- conduits positioned correctly and sealed

- handholes dry and accessible

- earthing/grounding installed per design

12. Common Mistakes (And How to Avoid Them)

Frequent issues we see in real projects:

- re-using “typical building footings” without wind/soil checks

- ignoring soil variation across the site

- using undersized or non-galvanized anchor bolts

- missing/poor grout installation

- conduit/handhole misalignment

- no documentation (no drawings, no load data, no calculation summary)

Most problems can be avoided with:

- a repeatable workflow

- practical drawings

- supervision at the right moments (rebar, bolts, concrete, grouting)

13. How Sunlurio Supports Street & Area Lighting Projects

Sunlurio is not only a manufacturer of LED street lights and steel poles. We support EPC and municipal projects with:

- poles, brackets and luminaires designed to work together

- HDG anchor bolt kits with steel templates

- base plate & anchor bolt drawings matched to pole models

- structural and wind load data for engineering checks

- preliminary foundation concepts based on your pole schedule and soil info

✅ Planning a project? Send your pole list, location and basic soil information.

👉 Send My Pole Schedule

👉 Talk to an Engineer

14. What About Solar Street Light Foundations?

This guide focuses on grid-powered street and area lighting poles.

Solar projects also need to consider:

- extra wind area of solar panels (sail effect)

- higher and more eccentric center of gravity

- battery pit design (waterproofing, condensation, anti-theft)

Related guide:

Solar Street Light Foundation Design: Wind Loads, Battery Pits & Safety

Download: Light Pole Foundation Design Toolkit

- Sample foundation calculation sheet (Excel)

- Typical spread footing drawing for 8–12 m poles (PDF)

- Site inspection checklist (PDF)

FAQs About Light Pole Foundations

1) How deep should a light pole foundation be?

There is no single fixed depth. It depends on wind load, soil bearing capacity and pole height. A rough estimate for direct-burial poles is embedment ≈ 10% of pole height + 600 mm (2 ft), but final depth must be confirmed by a qualified structural engineer with real project data.

2) What is a typical footing size for a 9–12 m street light pole?

Many municipal projects use reinforced spread footings in the range of 800×800×1200 mm to 1200×1200×1800 mm, depending on wind zone and soil capacity. These are typical ranges only—final design must be checked by calculation.

3) Do I always need an engineer to design light pole foundations?

Yes. Manufacturers and suppliers can provide typical loads and example foundations, but final design must be checked and signed off by a licensed engineer under local codes and regulations.