If you’ve ever stood with a procurement team under a “demo” solar street light in a district council yard, you know the routine. Everyone gathers right under the pole, someone says “wow it’s bright,” photos get taken… and two months later the site engineer calls you because the road is dark between poles, or the system starts dimming hard after two cloudy nights in the rainy season.

That’s the expensive part—not the fixture. The expensive part is rework: extra poles, extra foundations, angry community meetings, and rejected handovers by REA or TANESCO consultants.

When we evaluate solar street light performance for Tanzania’s infrastructure projects, we keep it defensible and measurable:

- Average illuminance (Eavg, lux)[^1]: Is the area bright enough overall?

- Uniformity (U0 = Emin / Eavg)[^2]: Is the light spread even enough to avoid “zebra striping” (black patches)?

- Rainy-day autonomy (days)[^3]: Will it stay compliant through the March–May rains, not just on sunny weeks?

This guide shows a step-by-step method you can use on real roads with a lux meter, plus tender-ready pass/fail language—so you’re comparing suppliers on performance, not promises.

TL;DR for Tanzania EPCs

- Don’t accept “bright under the pole” as evidence. It’s the easiest trick to fake.

- Verify Eavg + U0 using a simple lux grid between two poles.

- Verify autonomy using the real schedule (not demo mode) and rainy-season assumptions.

- Win tenders with paperwork: IES/LDT + LM-80 + battery/BMS + IP reports—and an acceptance checklist that forces transparency.

Get a Free DIALux[^4] + Spacing Check (Tanzania Projects Only)

If you don’t want to risk a wrong lux calculation or unrealistic spacing in your BOQ, send us:

- Road width + road type (rural road / town road / junction)

- Pole height + spacing target

- Required operating hours + any dimming/motion logic

- Project location (coastal / inland / highland)

Within 12–24 working hours, you’ll receive:

1) A DIALux snapshot / layout assumptions (as required)

2) A spacing feasibility note (where uniformity fails first)

3) A tender-ready test/acceptance checklist[^5]

👉 Request the Free DIALux + Spacing Check

EPC / distributor projects only. No retail inquiries.

1) What “Lighting Performance” Actually Means

Lighting performance is the combination of photometric quality[^6] and energy reliability[^7].

In grid-tied lighting (TANESCO power), you mainly worry about optics. In solar, you don’t have that luxury. If you only check brightness under the luminaire, you’re basically judging the brightest point of a flashlight beam—feels good, tells you almost nothing about road safety.

Buyer-standard question (what acceptance teams actually care about):

Will this system maintain required lighting levels across the full road width, every night, including the rainy season—without forced early dimming or “survival mode” complaints?

That’s why evaluation must include both:

- Photometrics (lux + uniformity across a measured grid), and

- Energy resilience (autonomy under low/zero charging conditions at the real operating schedule).

2) The Tanzania Factors That Kill Performance

Solar street light performance is driven by a chain reaction between configuration, geometry, and climate.

A) Heat Fade (Dodoma & Central Regions)

Battery temperature affects usable energy and lifetime. If a supplier quotes “battery capacity” without stating usable Wh under operating temperature[^8], you’re guessing.

What to check:

- usable Wh / DoD assumptions

- protection behavior at high temperature

- whether the schedule is stable or collapses into low mode

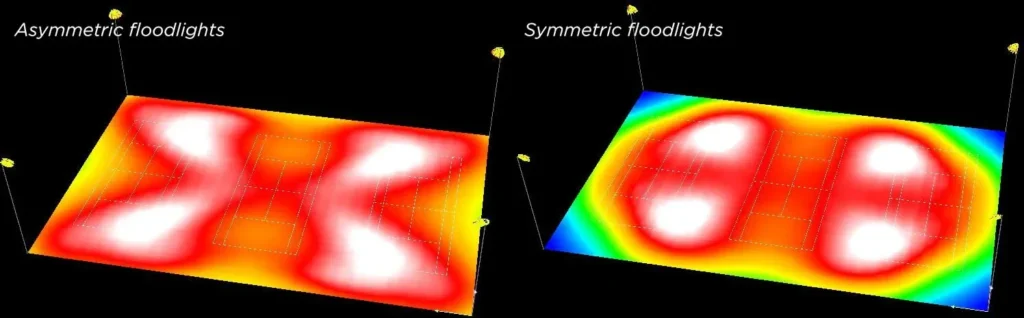

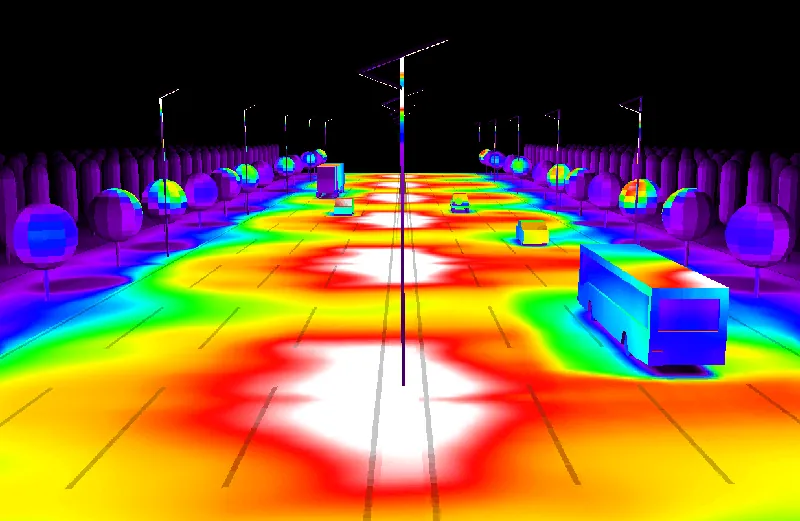

B) Optics & Uniformity (The “Between Poles” Problem)

Optics decide whether the light is a controlled road distribution or a hotspot.

The trap: narrow optics can look impressive under the pole but create dark gaps.

The fix: road distribution[^9]s (Type II/III style patterns) that push light sideways to raise Emin.

C) Rainy Streaks (Coastal & Highland Zones)

Autonomy must be sized for consecutive low-charge days, not “one bad day.” When rains come to Mwanza or Dar es Salaam, they don’t arrive politely one at a time.

What to check:

- autonomy claim tied to a schedule (hours + dimming)

- panel-to-battery ratio and worst-month assumptions

- whether “autonomy” means real brightness or faint glow

3) How to Verify Average Illuminance (Eavg)

What is Average Illuminance (Eavg)?

Eavg is the arithmetic mean of lux readings across your target surface area.

Peak lux under the pole is not Eavg.

Field method (repeatable, procurement-proof)

Do not let the supplier hold the meter. Use a simple grid over one pole span:

1) Stabilize mode: measure at night after the lights run ~30 minutes in the real schedule (not demo).

2) Define one span: measure between two poles on the same side.

3) Mark a grid: 10 equal points along the span (add more if spacing is large).

4) Measure across width: keep positions consistent (edge / mid-lane / far side, depending on road).

5) Record lux: at a consistent height (ground plane) without shadowing the sensor.

6) Calculate Eavg: sum of readings ÷ number of readings.

7) Log conditions: weather, road surface wet/dry, time, mode, battery state.

Common tricks that inflate Eavg (watch these):

- measuring only under the pole (peak ≠ average)

- testing in 100% mode when the real schedule dims

- not defining target area (carriageway only vs sidewalks/shoulders)

- wet reflective surfaces without noting conditions

EPC Toolkit: Copy/Paste Tender & Acceptance Clause

Use this block to stop “demo tricks” and reduce acceptance disputes:

Tender clause (photometric acceptance):

Supplier shall provide IES/LDT photometric files for the offered model. Road lighting performance shall be verified by DIALux (or equivalent) simulation using the provided photometry and the project’s mounting height, spacing, and road width.On-site acceptance shall include a lux grid test over one pole span (between two poles), using the actual operating mode/schedule (including dimming settings).

Acceptance records shall include measured Eavg, measured Emin, and calculated Uniformity U0 = Emin/Eavg, along with date/time, road condition (wet/dry), and the verified lighting mode used during testing.

4) Uniformity (U0): The Safety Metric

What is Uniformity (U0) and how do you calculate it?

Uniformity (U0) = Emin ÷ Eavg, using the same grid data.

Uniformity tells you whether the darkest point is acceptable. If Emin collapses, people see “black holes” even when average lux looks fine.

Practical targets (tender-friendly)

Targets depend on application, but procurement needs numbers:

- Conflict areas (junctions/roundabouts): a common target is U0 ≥ 0.40 (often referenced in EN 13201-style guidance for conflict areas).

- Rural roads: enforce a minimum acceptable Emin and avoid “zero lux” gaps between poles.

Best lever: optics + geometry.

Uniformity is improved by better distributions and correct spacing, not by blindly increasing wattage (which hurts autonomy).

5) Rainy-Day Autonomy: The Survival Metric

Autonomy is not “the LED is faintly glowing.” It means:

the light stays above your required brightness profile for X full nights without meaningful charging.

Field test (simple, hard to argue with)

1) Fully charge the system.

2) Block/disable charging safely to simulate “no sun.”

3) Run the real schedule nightly.

4) Each night, confirm the light remains in the required mode (not secretly collapsing).

5) Autonomy (days) = number of full compliant nights.

Red flag: some lights “fake” autonomy by dropping to 10–20% after a few hours.

Your tender should require the schedule profile to be disclosed and verified.

6) The Paperwork That Actually Wins Tenders (REA / Donor / Consultant Reality)

Strong documentation turns evaluation from “trust me” into “prove it.”

Minimum pack that serious EPCs should ask for:

1) IES / LDT files (for simulation and optics verification)

2) LM-80 / LED reliability evidence (or equivalent supporting documents)

3) Battery + BMS evidence (cycle life basis, protection behavior, usable energy assumptions)

4) IP test reports (not stickers—real lab output)

5) Warranty terms linked to configuration and usage conditions

Free “Red Flag Audit” (Avoid Tender Rejection & Rework)

Already have a supplier quote or datasheet?

Send us:

- datasheet / brochure

- battery spec (Wh, chemistry, cycle claim basis)

- photometry claim (IES/LDT availability)

- dimming schedule claim

We’ll reply with a Red Flag Audit highlighting common risk points:

- “demo-bright but fails between poles”

- unclear dimming logic / hidden low-mode

- missing test evidence

- unrealistic rainy-season autonomy assumptions

👉 Request a Free Red Flag Audit

Strictly B2B.

7) Reverse-Engineer the Right Spec (Stop Buying by Wattage)

Don’t start with “I need a 60W light.” Start with the road:

1) Define road width and target coverage zone

2) Define pole height and spacing constraints

3) Define targets (Eavg + U0/Emin + autonomy days)

4) Select optics and spacing that can meet uniformity

5) Set the operating schedule (hours + dimming/motion)

6) Size usable battery energy and panel charging margin for worst-month conditions

Sanity check: if someone promises “100W brightness” from a tiny panel and a tiny battery with no photometry proof—walk away. Physics is physics.

8) Summary Checklist (What to Ask in Tanzania)

- Ask for DIALux simulation + IES/LDT, not just a brochure

- Ask for uniformity proof, not peak lux under the pole

- Ask for autonomy days for rainy season, tied to a disclosed schedule

- Ask for a compliance pack upfront (photometry + battery/BMS + IP reports, etc.)

Request the Tanzania Performance & Compliance Pack (EPC Projects Only)

Send your BOQ or road parameters (road width, pole height, spacing, target lux/uniformity, rainy-season autonomy requirement).

Within 12–24 working hours, you’ll receive a project-ready pack:

- DIALux snapshots / layout assumptions (if required)

- Acceptance test form (Eavg, Emin, U0 + mode verification)

- Compliance document checklist (IES/LDT, battery/BMS, IP reports, etc.)

- A clear configuration direction to reduce BOQ rework risk

👉 Contact Sunlurio for the Performance & Compliance Pack

No retail / household inquiries.

---

[^1]: Learn the calculation methods for Eavg to ensure your lighting meets safety and visibility standards.

[^2]: Explore why uniformity is crucial for road safety and how it impacts lighting design.

[^3]: Discover the importance of autonomy in ensuring reliable lighting during adverse weather conditions.

[^4]: DIALux is a powerful tool for simulating lighting; understanding it can enhance your project planning.

[^5]: A comprehensive checklist can streamline the acceptance process and reduce disputes.

[^6]: Understanding photometric quality can help you select better lighting solutions for safety.

[^7]: Explore the concept of energy reliability to ensure your solar lights perform consistently.

[^8]: Understanding usable energy can help you choose the right battery for your solar lights.

[^9]: Discover how road distribution affects light spread and visibility on roadways.