Notes from 15 years of projects across East & Central Africa — where wind, steel, procurement shortcuts, and sometimes stubborn consultants all collide in the real world.

What Wind Ratings Actually Mean for Lighting Poles

Wind rating is basically the “survival number” of your pole — the maximum wind speed it can endure with all attachments mounted.

Most EPC teams look this up when they’re torn between price, compliance, and what the local authority actually demands.

People often think it’s just a number on a datasheet… but that number hides EPA, drag, pole geometry, and a bunch of decisions that get made by procurement under pressure. And that’s usually where things start slipping.

A quick way to explain it to a client:

Higher wind rating = stronger pole → more stability → fewer surprises after storms.

But of course, the devil is in the details.

How Engineers Decide Wind Performance (and Why It’s Not as Neat as It Looks)

Understanding EPA — the Part Everyone Underestimates

EPA is the effective projected area, or the “wind-catching surface” of everything bolted onto the pole.

It includes:

- Luminaires

- Brackets

- Solar panels (massive EPA, honestly)

- CCTV housings

- Even that little WiFi box someone adds later without telling anyone

I once handled a project in Eldoret where procurement swapped the originally approved LED fixture for a “cheaper but similar” model. Looked the same. But the fins were wider, EPA almost doubled. Nobody recalculated.

After about 18 months, the poles didn’t break — they slowly leaned. A few degrees each season. The client assumed soil failure… nope, pure EPA overload.

Funny how small decisions echo years later.

Drag Coefficient — Why Shape Matters More Than People Think

Cd is how “slippery” an object is against the wind. Two fixtures can be the same size but behave completely differently.

Common Cd values I usually work with:

- Round poles: 0.5–0.7

- Square/octagonal: 1.2–1.4

- Floodlights: around 1.1–1.4

- Solar panels: roughly 1.2–1.3 (and worse when angled wrong)

Most teams realise this after the first unexpected vibration. Not before.

How Pole Wall Thickness Really Affects Wind Performance

Pole gauge is simple: lower gauge = thicker steel = stronger pole.

Yet I still see gauge numbers misunderstood in tender documents.

A few years back in Lusaka, a contractor forced a change from 7-gauge to 10-gauge “to save cost”. Looked fine on day one.

Three years later: micro-cracks around the base, tiny but growing. Fatigue failure creeping in. No storm, no drama — just gradual weakening. Hard to explain to the auditor afterwards.

So yes… gauge matters. More than most budget committees want to admit.

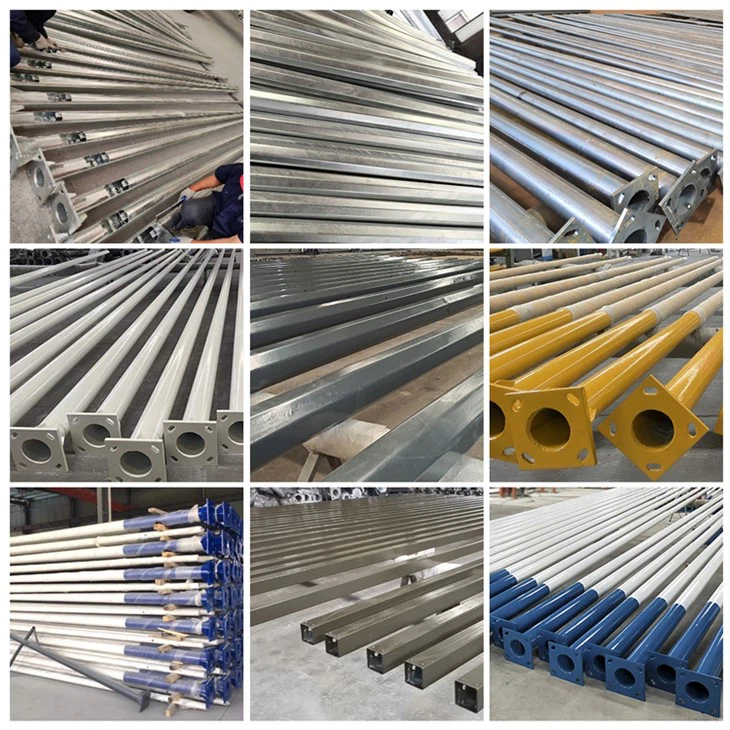

Material & Shape — Where Personal Preference Sneaks In

Different materials behave differently:

- Steel: strong, predictable. My default for almost every serious project.

- Aluminum: light, nice appearance… but honestly, I avoid it anywhere scrap theft or vandalism is common.

- Fiberglass/composites: corrosion-resistant but not my choice for high wind. They flex too much.

- Galvanized steel: best balance for African climates.

Shapes matter too:

- Round poles: best wind performance

- Octagonal: decent compromise

- Square: I only approve these when EPA stays tiny — their drag is no joke

People sometimes forget: aesthetics don’t matter much once the wind shows up.

How Different Wind Rating Categories Actually Apply in Real Projects

Standard Wind Ratings — the “Everyday Poles”

Usually about 70–90 mph.

Best for:

- Normal roads

- Estates

- Car parks

- Inland towns with mild weather

If EPA stays low (say, under 2 ft²), these poles live a long, happy life.

When Do You Need Higher Wind Ratings?

Think 90–120 mph conditions.

These matter in:

- Coastal towns like Mombasa

- Highland areas with unpredictable gusts

- Ports and open industrial zones

One thing we sometimes forget: it’s not just strength — stiffness matters.

A pole that doesn’t break can still shake fixtures to death.

What Hurricane-Level Ratings Really Mean

130–150+ mph ratings involve much heavier construction:

- Thick plate bases

- 5–7 gauge steel

- Deep foundations

- Round tapered shapes only

- Fixtures with very low EPA

We supplied some after Cyclone Idai in Beira. Clients didn’t argue price that year.

Trauma changes design philosophy more than engineering textbooks.

Choosing the Right Wind Rating Without Overthinking (or Underengineering)

Matching Wind Ratings to Local Requirements

Check local wind maps, but take them with context:

- South Africa’s SANS zones are detailed but often conservative inland

- Kenya’s coastal requirements jump significantly compared to Nairobi

- Nigeria varies wildly — Lagos is not Kano

- North Africa has nasty seasonal storms

- Island nations… well, they know what cyclones do

Sometimes the local authority’s requirement doesn’t match reality on site — happens more than it should.

A Human-Friendly Way to Calculate EPA

- Add luminaire EPA

- Add bracket EPA

- Add solar panel EPA (if any)

- Add accessories

- Multiply by Cd

- Compare with pole rating tables

Example (a very real one):

- LED fixture: 0.8

- Double-arm bracket: 1.0

- CCTV dome: 0.6

Total: 2.4 ft²

After Cd: around 3.0 ft²

Yet teams still choose poles rated for 2.0 ft² because “spec said so”.

Matching Fixtures to Structural Limits (The Part People Skip)

Before approving a pole, check:

- Height vs. load

- Wall thickness

- Base-plate & bolt pattern

- Arm length

- Weight distribution

Underengineering bends poles.

Overengineering burns budget.

Most projects land somewhere in between — or should.

The Mistakes I See Almost Every Month

Instead of a perfect checklist, here’s how it usually plays out on real sites:

Teams ignore bracket EPA.

(Happens in almost every coastal tender I review.)

Someone assumes aluminum = steel.

Then wonders why poles shake after 6 months.

Gauge numbers get misread.

People think 14-gauge is thicker than 10-gauge. It’s not, and the pole will tell you the truth later.

Late attachments suddenly appear — WiFi, CCTV, small signage.

Tiny things, big consequences.

Using overseas standards blindly.

I had a consultant insist on European pole specs for a project in Kisumu; they didn’t match local soil bearing capacity at all.

Beautiful drawings, wrong reality.

Most mistakes aren’t mechanical. They’re human.

What Actually Helps Poles Survive Wind Long-Term

Not a clean list — just what actually works:

- Get proper structural calcs. Most cheap suppliers avoid them.

- Verify EPA for every attachment — even that “small sensor”.

- Use good galvanization; wind + corrosion = slow disaster.

- Check foundations. Soft soil makes strong poles look weak.

- Re-tighten bolts in the first 6–12 months. Almost nobody does this.

- Treat coastal zones as high-risk by default, even if the tender doesn’t say so.

- And please — don’t add CCTV after installation without reviewing loading.

Sometimes the simplest habits save the most headaches.

FAQs

What wind rating do I actually need?

Rough guide: about 70–90 mph inland, 100+ mph coastal.

Does EPA really affect pole size that much?

Yes. It’s the biggest factor, more than weight.

Do taller poles require higher ratings?

Absolutely — height multiplies bending moment.

Can small attachments reduce wind rating?

Every single time. CCTV is the silent killer of pole specs.