Coastal cities across Africa, the Middle East, and Asia are investing in solar street lighting to improve safety, reduce energy bills, and achieve sustainability targets. Yet one overlooked factor decides whether a project lasts decades or fails within a few years: the pole material and coating.

In coastal regions, salty air and high humidity make corrosion much faster. Painted poles often rust through in less than five years, leading to safety risks and extra replacement costs. For governments, anti-corrosion poles are essential for solar projects near the coast.

Why Do Coastal Solar Projects Need Anti-Corrosion Poles?

In short: painted poles cannot resist coastal conditions. Only galvanized or specially coated poles can last 20–30 years.

Challenges of coastal environments:

- Salt spray: Direct attack on steel surface.

- Moisture and humidity: Rust grows fast.

- Strong winds: Weak poles corrode and break faster.

Without strong protection, poles fail long before the lights reach mid-life.

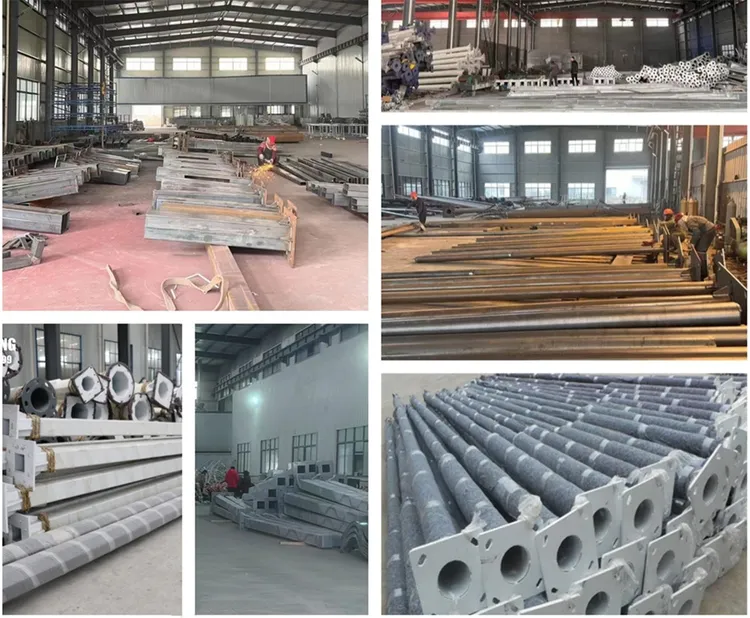

What Anti-Corrosion Solutions Are Available for Poles?

In short: hot-dip galvanization, duplex coating, and stainless steel.

| Pole Type | Protection Method | Lifespan (Coastal) | Cost Impact |

|---|---|---|---|

| Painted steel | Spray paint only | 3–5 years | Low |

| Hot-dip galvanized | ≥85μm zinc coating | 20–30 years | Medium |

| Duplex system | Galvanization + epoxy paint | 25–35 years | Medium-High |

| Stainless steel | Marine-grade alloy | 30+ years | High |

For government tenders, hot-dip galvanized poles (ISO 1461 standard) give the best balance between cost and durability.

How Do Anti-Corrosion Poles Save Money for Governments?

In short: they reduce lifecycle cost by avoiding early replacements.

Example for 1,000 poles:

- Painted poles: last 4–5 years → replaced 2–3 times in 20 years.

- Galvanized poles: last 20+ years → no replacement.

Result: 40–60% lifecycle savings.

Additional benefits:

- Lower maintenance budgets

- Reduced safety incidents

- More stable lighting uptime

What Standards Should Be Required in Tenders?

In short: EN 40 + ISO 1461 + ISO 12944.

Checklist for procurement:

- Hot-dip galvanization thickness ≥85μm

- Salt-spray test ≥720h (ISO 9227)

- Duplex system for high-salt marine zones

- Weld and structure tests per EN 40

These requirements ensure poles last as long as the solar lights.

Real-World Cases of Coastal Projects

- Lagos, Nigeria: 500 galvanized poles installed in 2014 still working well after 10 years.

- Tema, Ghana: Painted poles installed in 2016 had severe rust after 4 years, forcing early replacement.

This is why more government projects now specify hot-dip galvanized poles.

Why Poles Should Be a Priority, Not Afterthought

Solar projects often focus on LED efficiency (≥230 lm/W) or battery cycle life (≥6000 cycles). But the pole is the backbone. If the pole fails, the entire system is lost, no matter how good the components are.

- Painted poles fail fast in coastal regions.

- Hot-dip galvanized poles provide 20–30 years of service.

- Lifecycle cost savings reach 40–60%.

- Governments should demand EN 40 + ISO 1461 + ISO 12944 compliance.

- Sunlurio provides tested anti-corrosion poles for coastal projects.

For projects near the coast, do not risk failure with painted poles. Ask for our technical datasheet on galvanized and duplex-coated poles and secure 20+ years of reliable operation.