Manufacturing Quality Lighting Poles for Every Project

Products Overview

Say Goodbye to Rust – Durable Hot-Dip Galvanized Street Light Pole Manufacturer

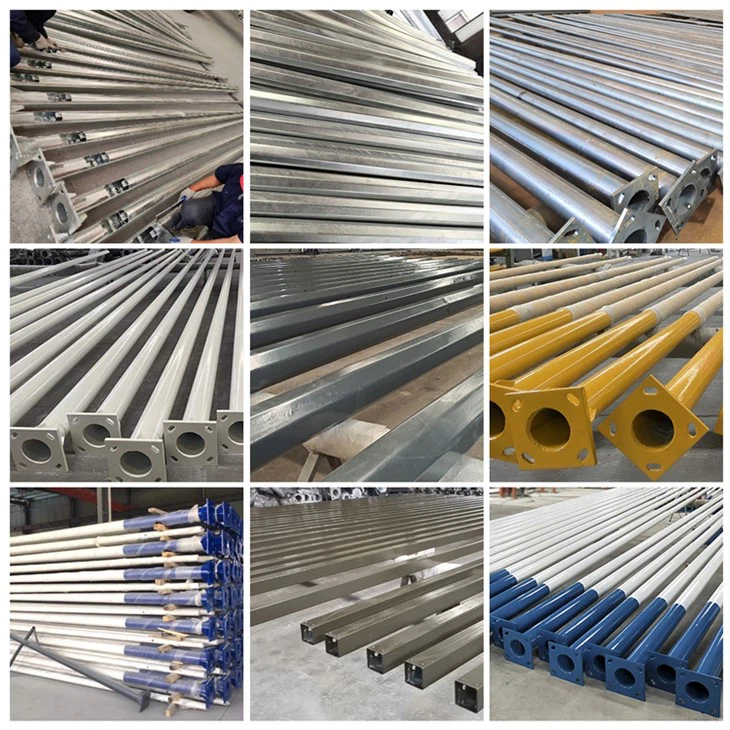

Hot-dip galvanized street light poles are designed and manufactured for superior durability, corrosion resistance, and long-term outdoor performance. Each pole undergoes a strict hot-dip galvanizing process—steel is immersed in molten zinc to create a uniform, metallurgically bonded coating that protects against rust in all weather conditions.

- Premium hot-dip galvanizing: Steel is fully immersed in molten zinc for complete surface coverage, preventing rust and oxidation.

- Corrosion & weather resistance: Ideal for coastal, humid, and high-rainfall regions where ordinary poles deteriorate quickly.

- Long service life: Zinc layers bond to the base metal, extending pole lifespan for decades with stable field performance.

- Professional manufacturing process : Advanced manufacturing ensures uniform coating thickness, smooth finish, and consistent quality.

- Cost-effective over time: Reduced maintenance and repainting cut total lifecycle cost for public lighting projects.

- Customizable options: Multiple heights, top diameters, and bracket designs to match solar or grid street lighting systems.

- Strong load capacity: Engineered to safely support various luminaires, arms, and accessories.

- Reliable manufacturer support: End-to-end design, production, and export-ready packaging for project requirements.

No More Bending or Rust – High-Strength Steel Lighting Pole Manufacturer

Ordinary poles often fail under harsh weather, rust quickly, or lose stability over time. Our steel lighting poles solve these challenges with superior material strength, precision welding, and advanced surface protection. Each pole is manufactured using high-tensile Q235/Q345 steel to ensure reliable performance and a longer service life for every lighting project.

- High-tensile steel material: Built from premium-grade Q235/Q345 steel for exceptional strength and wind resistance.

- Corrosion-resistant finish: Hot-dip galvanizing or powder coating prevents rust and reduces maintenance needs.

- Excellent load capacity: Designed to withstand heavy luminaires and strong wind conditions without bending or cracking.

- Precision manufacturing: Automated manufacturing ensures uniform wall thickness, smooth welding, and accurate dimensions.

- Stable structure design: Tapered and octagonal shapes provide excellent balance between strength and weight.

- Flexible customization: Heights, diameters, arm types, and finishes can be tailored to project requirements.

- Extended lifespan: Durable steel construction guarantees decades of performance with minimal upkeep.

- Reliable steel lighting pole manufacturer: Supplying long-lasting , cost-effective solutions for roads, parking lots, and solar lighting systems.

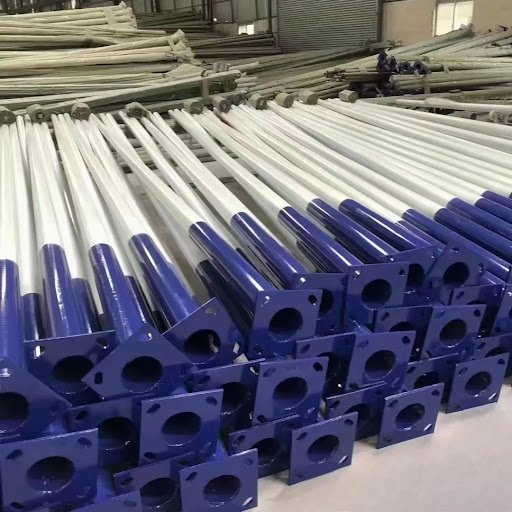

Faded Paint? Rust Problems? Upgrade to Powder Coated Steel Lighting Poles

Traditional painted poles often fade, peel, or rust after only a few seasons. Our powder coated steel lighting poles solve these issues with a durable, electrostatically applied coating that bonds tightly to the steel surface. As a professional steel lighting pole manufacturer , we use advanced powder coating technology to deliver both beauty and protection that last for years.

- Superior surface protection: The powder coating forms a dense, uniform film that resists corrosion, UV rays, and moisture.

- Long-lasting color and gloss: Fade-resistant finish keeps poles looking new even under intense sun exposure.

- No peeling or cracking: Unlike liquid paint, powder coating fuses to the metal surface for maximum adhesion and toughness.

- Eco-friendly process: 100% solvent-free coating—no VOC emissions, safe for people and the environment.

- Custom color options: Available in matte, glossy, or textured finishes to match cityscapes or project themes.

- Corrosion & impact resistance: Perfect for coastal areas, highways, and public spaces with heavy wear and weather exposure.

- Precision manufacturing: Each pole is pre-treated, cleaned, and manufactured to international quality standards.

- Reliable manufacturer support: Hitech provides design, surface treatment, and export packaging tailored to project needs.

Rust-Free and Lightweight – Professional Anodized Aluminum Lighting Pole Manufacturer

Ordinary steel poles often rust, fade, or require constant repainting in coastal and humid regions.

Our anodized aluminum lighting poles offer a superior solution — combining the natural

corrosion resistance of aluminum with the enhanced durability of the anodizing process.

Each pole is engineered and manufactured for long-term outdoor performance with an elegant,

maintenance-free finish.

- Rust and corrosion protection: The anodized aluminum surface forms a hard oxide layer that resists moisture, salt, and UV exposure.

- Lightweight yet strong: Easier to transport and install while maintaining high structural stability and wind resistance.

- Beautiful metallic finish: Smooth, modern appearance that retains its color and gloss without peeling or cracking.

- Ideal for harsh environments: Perfect for coastal cities, resorts, and tropical projects where steel poles deteriorate quickly.

- Custom anodizing options: Available in silver, bronze, or black finishes to match architectural or urban design themes.

- Maintenance-free design: No repainting or polishing required — saving time and long-term cost.

- Reliable aluminum lighting pole manufacturer: Delivering high-quality, corrosion-proof solutions for global lighting projects.

A Global OEM Factory Specializing in Solar Street Lighting

Comprehensive Solar Street Lights Solutions

Unmatched Quality & Price

We are an OEM/ODM manufacturer, ensuring unwavering quality control and unbeatable pricing. Our dedicated technical and service team is here to deliver the best solutions.

Unified Professional Team

Our unified technical team offers clients unparalleled solutions for every unique project, leveraging their expertise to meet your needs.

15 Years of Export Experience

With 13 years of production and export experience, we have undertaken projects across Africa, Europe, and Southeast Asia. Our extensive experience in government projects allows us to provide unrivaled advice on solar products.

Unique Customization Options

We offer products with unique specifications according to customization needs, ensuring that each client receives a solution tailored to their specific requirements.

Fast Delivery

We accept small orders and provide ultra-fast delivery services, ensuring that you receive your products promptly.

Comprehensive Support

Our professional team is ready to offer comprehensive support and advice on your projects, ensuring successful implementation and satisfaction.

Explore Our Factory Workshop – Professional Street Light Pole Manufacturer

Advanced Production Equipment

Our factory is equipped with modern CNC machines, automatic welding systems, and hydraulic bending equipment. These advanced facilities enable us to produce lighting poles with precise dimensions, uniform wall thickness, and excellent structural strength for various project requirements.

Strict Quality Control Process

Every pole is manufactured under a strict quality management system. From raw material inspection to final testing, our engineers monitor each stage to ensure durability, safety, and compliance with international standards before delivery.

Safe Packaging & Efficient Delivery

By manufacturing our own light sources, we ensure the quality and performance of the lighting, while reducing costs, providing customers with superior and more economical lighting solutions.

Professional Surface Treatment Lines

We operate our own galvanizing and powder coating workshops to protect every pole from corrosion, rust, and harsh environments. The surface finish is smooth, long-lasting, and customizable in color and gloss to meet different project aesthetics.

2010~2024 year Togo: 13,000 sets of solar street lights

2015~2020 year Ghana: 12,000 sets of solar street lights

2012 year Cote d'Ivoire: 890 solar street lights

2022 year Nepal: 200 solar street lights

2025 High Mast Lighting Project, Lusaka, Zambia

2023 year Cambodia:12,000 sets of solar street lights

... ...

Why Choose SunLurio?

At SunLurio, we don’t just assemble solar street lights — we engineer long-life outdoor lighting systems designed for real-world performance. Each unit is tested for brightness, corrosion resistance, and battery endurance before shipment. From African highways to coastal parks in Southeast Asia, our lights deliver consistent illumination for 3–5 rainy days, ensuring safety and sustainability everywhere.

Finished Projects

Years Experience

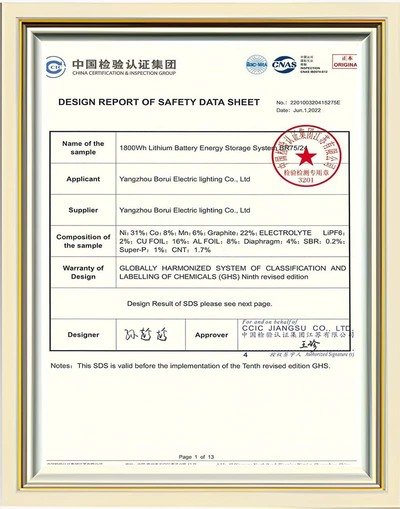

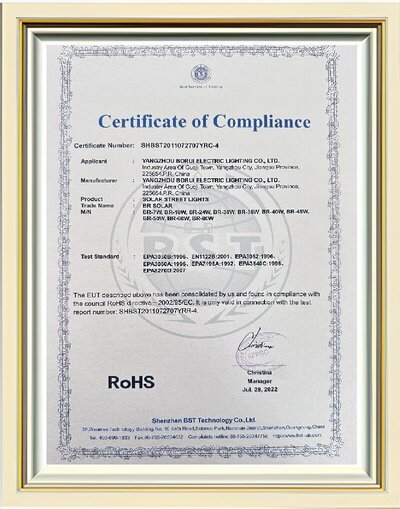

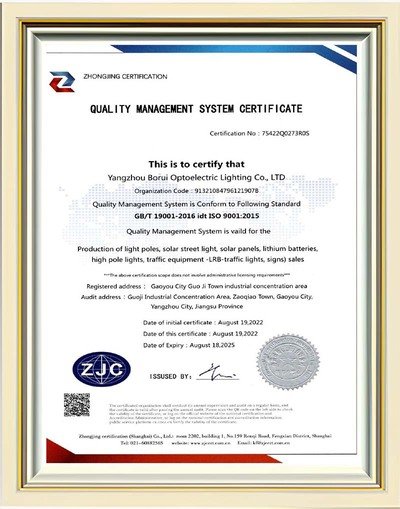

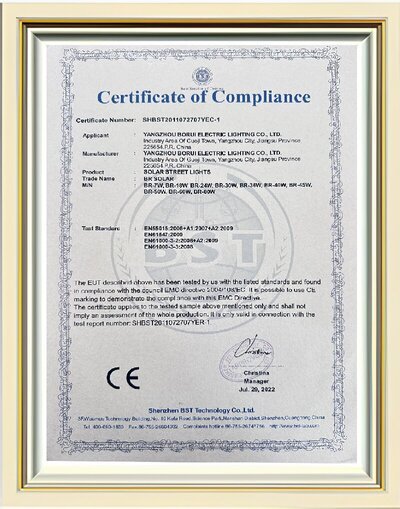

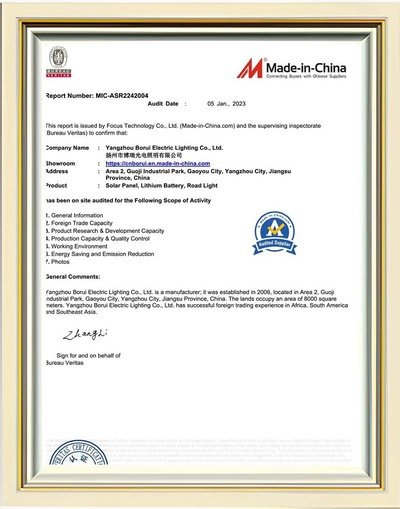

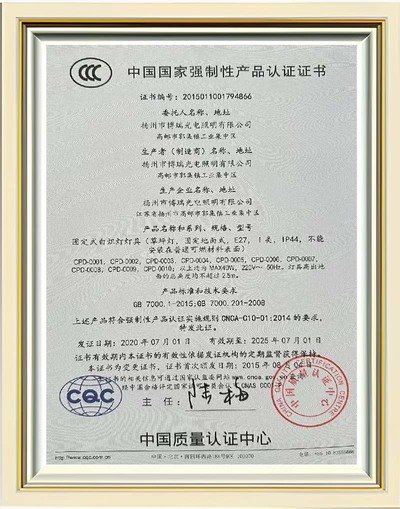

Certification Show

Qingdao Hitech New Energy Co., Ltd. (Sunlurio) holds ISO 9001, CE, and RoHS certifications, ensuring top-quality and environmentally responsible products.

What should I confirm before buying a lighting pole?

Material Type:

Choose the right material based on your environment — steel, hot-dip galvanized, powder coated, or anodized aluminum. Example: coastal or humid areas need corrosion-resistant materials like galvanized steel or aluminum.

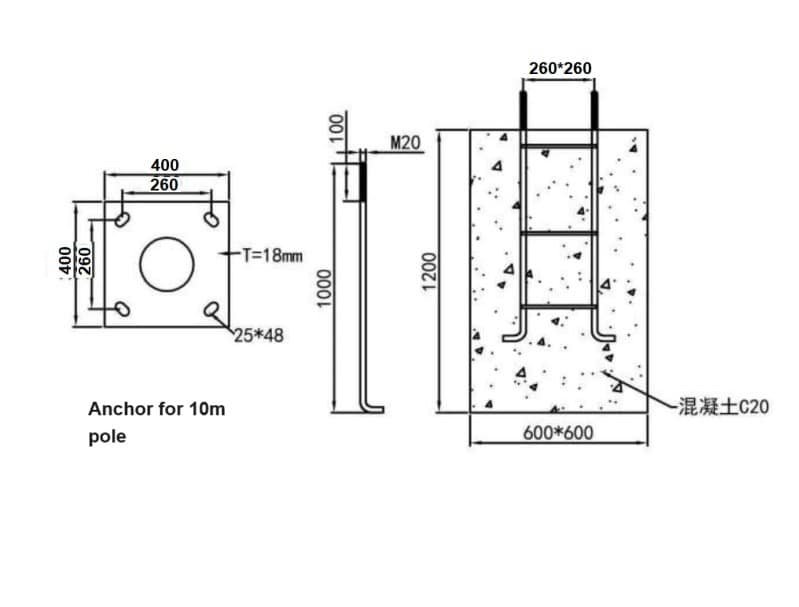

Pole Height and Design:

Confirm the required height, shape (round, conical, octagonal), and arm configuration according to lighting layout, road width, and illumination coverage.

Wall Thickness and Strength:

Check the pole’s thickness, wind resistance, and load capacity to ensure it can safely support the luminaire and bracket under local wind conditions.

Surface Treatment:

Verify the surface finish — galvanizing, powder coating, or anodizing — for protection against rust, UV, and weather exposure.

Split Light Pole – Easy to Transport, Easy to Install

Traditional one-piece light poles are heavy, difficult to transport, and require special handling during installation.

Our split light pole design eliminates these challenges with a two-section structure that can be easily assembled on-site without welding or large equipment.

As a professional lighting pole manufacturer , we developed this design to reduce transportation volume, simplify installation, and maintain the same structural strength and appearance as a single-piece pole.

Each section is precisely manufactured using advanced forming and machining equipment to ensure perfect alignment and stable connection after assembly.

This innovation not only lowers shipping and labor costs but also improves efficiency for contractors working in remote or large-scale projects.

With customizable height, diameter, color, and connection types, our split light poles provide a flexible solution for modern solar and street lighting applications.

Key Benefits:

Solves high shipping cost and difficult handling problems

Quick and safe assembly without welding or heavy machinery

Precision manufacturing ensures strong, stable connections

Compact packaging saves storage and transport space

Custom manufacturing available for different project requirements

How High Should My Lighting Pole Be?

| Application Area | Recommended Pole Height | Description / Notes |

|---|---|---|

| Residential street / small road | 5 – 7 m (16 – 23 ft) | Provides sufficient illumination for narrow streets and low-traffic areas. |

| Township / urban road | 8 – 10 m (26 – 33 ft) | Ideal for public roads, community areas, and standard solar street light setups. |

| Highway / main road | 10 – 12 m (33 – 39 ft) | Ensures wider light distribution and better uniformity for higher-speed traffic. |

| Parking lot / public square | 8 – 10 m (26 – 33 ft) | Balances coverage and brightness for open areas. |

| Industrial / commercial area | 9 – 12 m (30 – 39 ft) | Suitable for large working areas requiring stronger illumination. |

| Courtyard / garden / pathway | 3 – 5 m (10 – 16 ft) | Low-height poles create comfortable light for residential and decorative use. |

Professional Tip: Choose pole height based on lighting layout, luminaire power, beam angle, and site width. As a professional lighting pole manufacturer, we can design the optimal height and spacing for uniform illumination and cost efficiency.