When you’ve been around enough installations, you start noticing something simple — the poles tell their own stories. Some stand tall for decades, dull gray but solid. Others, glossy when new, begin flaking after the first rainy season. That’s really the story of hot-dip galvanized poles versus painted steel poles.

This isn’t a lab debate — it’s field reality. Corrosion doesn’t care about budgets, only chemistry and maintenance.

What Is a Hot-Dip Galvanized Pole?

A hot-dip galvanized pole is basically a steel pole dipped into molten zinc at about 450°C. The zinc reacts with steel, forming several metal-alloy layers that become part of the pole itself. Not just sitting on top — it’s a bond.

I’ve seen these come out of the tanks with that familiar gray matte finish, almost like a rough silver skin. The best part? Every edge, weld, and hidden corner gets coated.

- Full coverage, inside and out.

- Self-protecting zinc, meaning if scratched, the zinc still guards the steel underneath.

- Used everywhere: highways, solar lighting, power lines, even wind farms.

In harsh African climates, this process makes the difference between replacing poles every decade… or every generation.

What Is a Painted Steel Pole?

Painted poles, on the other hand, depend entirely on surface coatings — epoxy, polyurethane, powder paint, you name it.

The paint sits on top as a barrier, which sounds fine until real weather shows up.

Why they fail sooner than expected:

- Dust or oil wasn’t cleaned off before painting.

- UV rays crack the surface layer.

- Salt and humidity creep in through hairline gaps.

Once rust sneaks under the paint, it spreads invisibly. I’ve tapped poles that looked perfect on the outside, only to hear that hollow echo of corrosion beneath.

How Do They Actually Protect Steel?

| Feature | Hot-Dip Galvanized Poles | Painted Steel Poles |

|---|---|---|

| Protection type | Zinc acts as a sacrificial layer | Paint acts as a surface barrier |

| Failure risk | Low – zinc heals small scratches | High – once cracked, rust wins |

| Internal coverage | Full, even in welds | Mostly external only |

In one line:

Hot-dip galvanized poles protect steel chemically and physically, while paint just covers it — until the weather wins.

Which One Lasts Longer in the Real World?

Galvanized poles can run 70–100+ years without serious maintenance. I’ve seen 15-year-old installations near Lake Victoria still look decent.

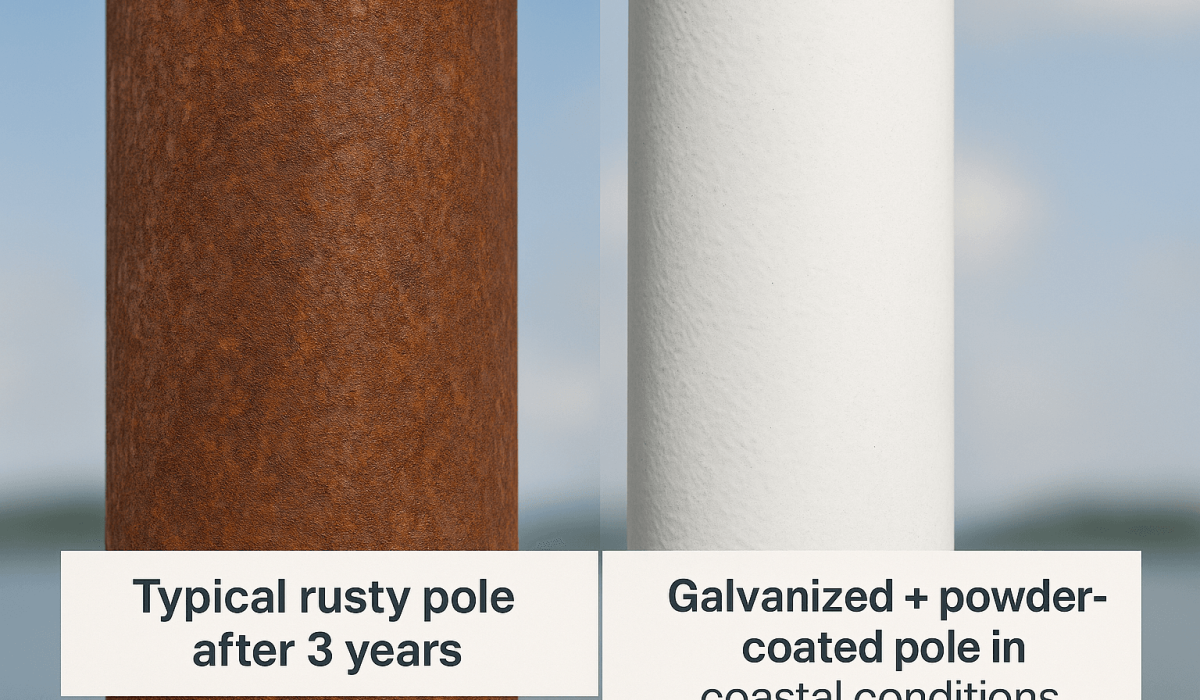

Painted poles? You’ll be repainting them in 3–5 years and maybe replacing them in 20.

Of course, humidity, salt, and pollution all speed things up — but galvanization handles those better than any paint system I’ve used.

In one project outside Mombasa, we tested both types side by side. After seven years, the painted poles were orange halfway up the shaft. The galvanized ones—only dusty.

Maintenance and Cost Over Time

People love to talk about initial cost. But it’s maintenance that drains the budget.

| Aspect | Hot-Dip Galvanized | Painted Steel |

|---|---|---|

| Maintenance cycle | Practically none | Repaint every few years |

| Average lifespan | 75–100 years | 20–30 years |

| 30-year total cost | Lowest | 2–3× higher |

That’s not a spreadsheet theory — that’s real project math. Over 20 years, paint always eats back the savings.

What About Looks?

I get it. Some city planners want color. Galvanized poles are simple — a flat, gray tone that blends quietly into the background.

Painted ones can look more “urban” or branded, sure. But five years later, that once-perfect blue might fade into dull patches.

You can always paint over galvanized steel later — but never the other way around.

Environmental Angle

Hot-dip galvanizing isn’t just tougher — it’s cleaner long term.

- Zinc and steel are recyclable.

- No paint fumes, no VOCs.

- Fewer trucks driving around for repaint jobs.

In our work, sustainability isn’t slogans — it’s fewer replacements and less waste dumped in roadside yards.

When Should You Use Which?

Here’s the quick take:

Go for Hot-Dip Galvanized Poles if:

- You’re installing in coastal, humid, or industrial areas.

- Maintenance access is tough or costly.

- You care about 30+ years of service life.

Use Painted Steel Poles if:

- You need custom colors or city branding.

- It’s a decorative or temporary project.

- You already plan for frequent upkeep.

I’ve mixed both in projects — galvanized for main roads, painted for city squares. Balance sometimes works better than perfection.

A More Honest Ending

Now, people like a clean conclusion, but real projects rarely are.

Hot-dip galvanized poles usually win — by a long shot — in lifespan, cost, and corrosion protection.

But if looks matter more than longevity, painted poles still have their place.

All I can say is this: I’ve never once had a client call to complain about a galvanized pole. Can’t say the same for painted ones.

Written with a bit of rust under my boots and too many inspection reports in my bag.