Hot-dip galvanization is the process of dipping steel poles into molten zinc to form a durable, rust-proof coating that protects against corrosion, weather, and mechanical wear. For solar street lights, this process ensures long-term strength, stability, and safety even in coastal or humid regions where steel would otherwise degrade quickly.

Solar street light poles are not just vertical supports — they handle heavy solar panels, controllers, wind loads, and daily exposure to rain, sun, and dust. Without proper protection, steel poles can corrode, weaken, or even fail structurally. That’s why hot-dip galvanization has become the global standard for professional solar street lighting projects.

Introduction: The Hidden Strength Behind Solar Street Light Poles

Solar street lights face continuous environmental stress — wind pressure, panel weight, and constant sun and rain exposure. To keep them stable and safe for years, the steel poles must be protected from corrosion and fatigue.

Hot-dip galvanizing is that protection. It forms a metallurgical bond between steel and zinc, creating a coating that not only blocks oxygen and moisture but also sacrifices itself to prevent rust from reaching the base metal.

In this article, we’ll explore what galvanization is, how it works, and why it matters so much for solar lighting projects across Africa and beyond.

Understanding the Demands on Solar Street Light Poles

Solar street light poles must endure both structural and environmental challenges:

- Support the weight of solar panels, controllers, and sometimes batteries.

- Resist wind torque, vibration, and occasional impact.

- Withstand humidity, rain, and dust without corrosion.

When a pole fails — it’s not just a broken part. It can cause lamp collapse, property damage, or even injury. This is why reinforcing and protecting the pole surface is not optional; it’s a safety requirement.

💡 Purpose: Before introducing galvanization, it’s important to understand the mechanical demands poles face — corrosion protection isn’t luxury, it’s essential.

What Is Hot-Dip Galvanization?

Hot-dip galvanization involves immersing cleaned steel into molten zinc, forming a strong zinc–iron alloy layer that bonds permanently to the surface.

This reaction creates dual protection:

- Barrier protection – blocks moisture and oxygen.

- Cathodic protection – zinc corrodes in place of steel if the surface is scratched.

Hot-Dip Galvanization Process Steps

- Cleaning and degreasing the steel surface

- Acid pickling to remove oxide layers

- Flux coating for adhesion improvement

- Dipping the pole into molten zinc (~450°C)

- Cooling, inspection, and thickness testing

This process ensures full coverage, both inside and outside the pole — something paint or powder coating can’t achieve.

Why Solar Street Light Poles Use Hot-Dip Galvanized Steel

4.1 Corrosion Resistance

Hot-dip galvanized coatings shield steel from oxygen, water, and pollutants. Zinc serves as a sacrificial layer, corroding slowly instead of the steel underneath — especially vital in humid or coastal environments.

4.2 Extended Service Life

Properly galvanized poles can last 20–50 years with minimal maintenance. There’s no need for repainting, which saves time and reduces total lifecycle cost.

4.3 Structural Strength Retention

Because rust causes microcracks and metal fatigue, the zinc coating prevents internal weakening. This means poles maintain full rigidity under heavy solar panels and strong winds.

4.4 Safety and Stability

By preventing corrosion-related deformation, hot-dip galvanization helps avoid dangerous pole bending or failure. This is crucial for large installations using heavy LED modules or battery-mounted designs.

4.5 Cost-Effectiveness

While galvanization adds 5–10% to the initial price, it cuts maintenance costs dramatically. Over 10 years, a galvanized pole often saves more than it costs upfront.

Hot-Dip Galvanizing vs. Other Protective Coatings

| Method | Description | Durability | Maintenance | Cost | Suitability |

|---|---|---|---|---|---|

| Hot-Dip Galvanizing | Steel dipped in molten zinc | 20–50 years | Very Low | Moderate | Best for outdoor/solar poles |

| Cold Galvanizing (Zinc Paint) | Zinc-rich coating applied by spray | 3–5 years | Medium | Low | Temporary protection |

| Powder Coating | Polymer-based decorative finish | 5–10 years | Medium | Moderate | Aesthetic use |

| Electroplating | Thin zinc layer via electrolysis | 2–3 years | High | Low | Indoor/light-duty use |

💡 Highlight: Only hot-dip galvanization provides full interior and exterior coverage — making it the only method truly fit for solar lighting poles exposed to harsh weather.

Advances in Galvanization Technology

Modern galvanizing plants use zinc–iron and zinc–phosphate compounds for stronger adhesion and better coating uniformity.

Automation now ensures stable dipping temperatures, even coating thickness, and cleaner finishes. Many facilities have also adopted eco-friendly recycling systems, reducing zinc waste and emissions — a growing focus for sustainable infrastructure manufacturers.

Common Quality Standards for Galvanized Poles

Internationally, hot-dip galvanization for steel poles follows:

- ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles.

- ASTM A123: Standard specification for zinc coatings by hot-dip process.

For solar street light poles, the recommended zinc layer thickness is 70–100 μm.

Common testing methods include:

- Adhesion tests

- Thickness measurement (magnetic gauge)

- Salt spray corrosion testing

Maintenance and Inspection Tips for Galvanized Light Poles

Even though galvanized poles need little care, basic inspections can extend their life:

- Check for scratches, dents, or impact marks.

- Look for dull gray spots — early signs of zinc wear.

- Inspect bolt corrosion at mounting or flange points.

- Clean with mild detergents; avoid acids or abrasives.

If damaged areas appear, touch up using zinc-rich repair paint to restore the protective layer.

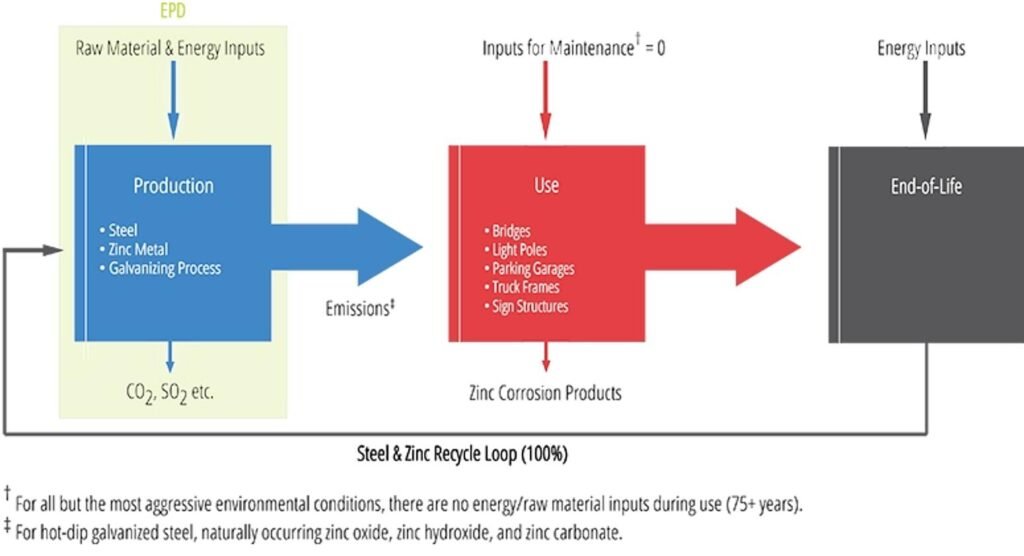

Environmental and Economic Benefits

Galvanized steel poles are sustainable in both use and lifecycle:

- Longer lifespan = less steel waste and manufacturing emissions.

- Zinc is 100% recyclable and non-toxic.

- Lower lifecycle cost — less frequent replacements and reduced labor.

For municipal and EPC projects, these savings compound significantly over years of operation.

Conclusion: Why Hot-Dip Galvanization Is Essential for Solar Street Lights

Hot-dip galvanization combines strength, corrosion resistance, and durability — the perfect match for solar street lighting systems that must last decades outdoors.

By choosing galvanized poles, project managers ensure safety, long-term performance, and reduced maintenance headaches.

Investing in hot-dip galvanized poles means your solar street lights stay safe, stable, and maintenance-free for decades.

Internal Link Suggestions

- Solar Street Light Price Analysis: Key Factors That Affect Cost

- Solar Street Light Specification Guide

- Corrosion Protection for Outdoor Solar Structures

FAQ Section

Q1: Why are solar street light poles galvanized?

Because galvanization prevents corrosion and extends the pole’s lifespan in harsh outdoor conditions.

Q2: How long does a hot-dip galvanized pole last?

Typically between 20 and 50 years, depending on coating thickness and environment.

Q3: What’s the difference between hot-dip and cold galvanizing?

Hot-dip involves immersing steel in molten zinc, forming a strong alloy bond. Cold galvanizing is just zinc-rich paint — it offers temporary protection only.

Q4: Does galvanizing affect steel strength?

No. Proper hot-dip galvanization doesn’t weaken steel; it actually preserves its mechanical strength by stopping rust.

Q5: Can galvanized poles be painted for aesthetics?

Yes, after surface preparation. Many municipalities apply powder coating on top for color and branding without affecting protection.