Choosing the wrong light pole material can lead to high maintenance costs and early replacements. Don’t let a short-term choice become a long-term problem.

Both aluminum and fiberglass offer durable, low-maintenance alternatives to cast iron—ideal for decorative and functional outdoor lighting.

If you're deciding between the two, this guide compares lifespan, installation, durability, and use cases—so you can make a confident choice for your next project.

Choosing the Right Decorative Light Pole Material?

Modern pole materials don’t just imitate the classic cast iron look—they improve on it.

Aluminum and fiberglass poles offer the aesthetic of traditional cast iron with modern benefits like corrosion resistance, lightweight construction, and flexible installation.

Why it matters:

- Municipalities and developers now prioritize appearance plus performance

- Decorative poles are used for streetscapes, parks, campuses, and waterfronts

- Cast iron is outdated: heavy, rust-prone, and expensive to install

Aluminum and Fiberglass: The Lightweight Cast Iron Alternatives?

Aluminum and fiberglass are changing the game for urban designers and contractors.

Both materials can replicate the fluted, decorative look of cast iron while being significantly lighter and easier to install.

Key shared traits:

- Classic or modern designs (fluted or smooth)

- Lighter than cast iron—easier to handle on-site

- Lower maintenance requirements

- Compatible with standard lighting arms, bases, and finials

Advantages of Aluminum Light Poles?

Aluminum is the go-to choice for long-term projects in cities and campuses.

With a lifespan over 50 years and high corrosion resistance, aluminum poles are ideal for urban, decorative, and commercial lighting applications.

Why choose aluminum:

- 50+ year lifespan with minimal maintenance

- Multiple finish options: powder-coated, anodized, or natural

- High structural strength: ideal for flagpoles, streetlights, and signage

- Flexible design: tapered, custom wall thickness, base style options

- Recyclable: sustainable choice for green-certified projects

Common applications:

- Main streetscapes

- University and commercial campuses

- Flagpoles in government buildings

- Architectural lighting in business parks

Advantages of Fiberglass Light Poles?

Fiberglass offers a corrosion-proof, lightweight alternative—perfect for harsh environments.

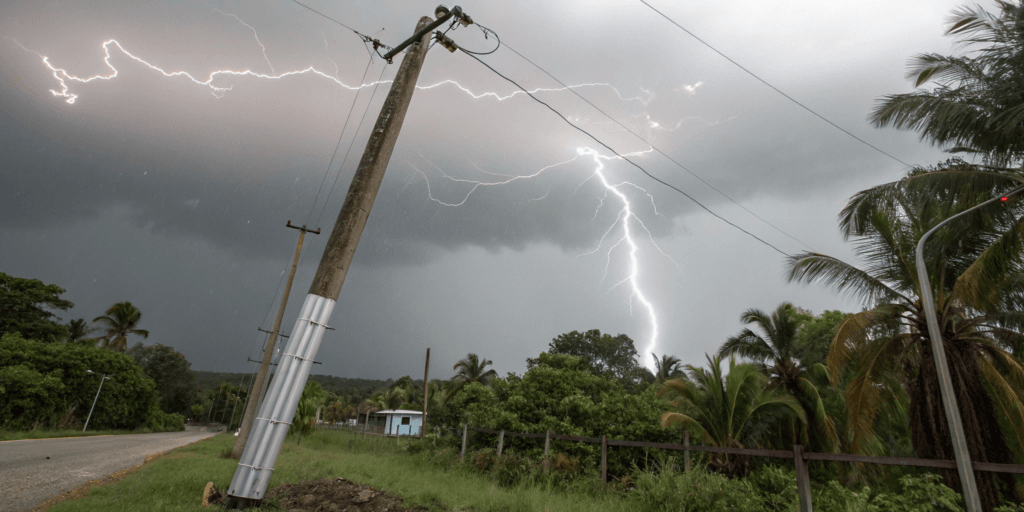

Fiberglass poles are nonconductive, impact-resistant, and ideal for salt-rich or high-wind locations.

Why choose fiberglass:

- Resistant to salt, fertilizer, and extreme moisture

- Nonconductive: safer in storm-prone or lightning-heavy areas

- Lightweight: easier and faster to install

- Direct burial friendly: no need for anchors or base plates

- Lifespan of 15–20 years: good balance of cost and durability

- Impact-resistant: holds up well in public spaces or storm zones

Ideal for:

- Coastal towns and beachfront promenades

- Parks with high public interaction

- Rural or tropical zones prone to lightning or humidity

- Municipal projects with lower upfront budgets

Key Comparison Table: Aluminum vs. Fiberglass Light Poles?

Use this table to compare core features side by side.

| Feature | Aluminum Poles | Fiberglass Poles |

|---|---|---|

| Lifespan | 50+ years | 15–20 years |

| Corrosion Resistance | High | Very High |

| Maintenance | Low | Low |

| Finish Options | Smooth or Fluted | Smooth or Fluted |

| Conductivity | Conductive | Non-conductive |

| Impact Resistance | Moderate | High |

| Ideal Environments | Urban, flags, commercial | Coastal, hurricane-prone, parks |

| Installation | Direct burial or anchor base | Direct burial or anchor base |

| Cost | Higher upfront, longer ROI | Lower upfront, medium ROI |

Use Case Scenarios: Which Pole Should You Choose?

Match your project needs with the right material.

Choose Aluminum If:

- You need a 50+ year lifespan

- You’re installing urban or municipal lighting

- You’re sourcing flagpoles or signage poles

- You want structural flexibility in taper, wall thickness, or base options

Choose Fiberglass If:

- You’re in a coastal, corrosive, or storm-prone zone

- You want nonconductive safety features

- You need quick and simple direct burial installation

- You’re working on parks, beachfront, or budget-sensitive projects

Installation Tip: Direct Burial vs. Anchor Base?

How you install your pole also affects cost and longevity.

Both aluminum and fiberglass poles can be installed with anchor bases or direct burial. Choose based on site conditions and project goals.

Pros and cons:

-

Direct Burial:

- Faster and cheaper to install

- No need for concrete bases or anchor bolts

- Ideal for fiberglass in park settings

-

Anchor Base:

- More durable in paved or urban areas

- Easier to replace or remove pole in future

- Often used with aluminum in streetscape projects

Tip: Always confirm soil type, frost depth, and wind zone rating before choosing your foundation type.

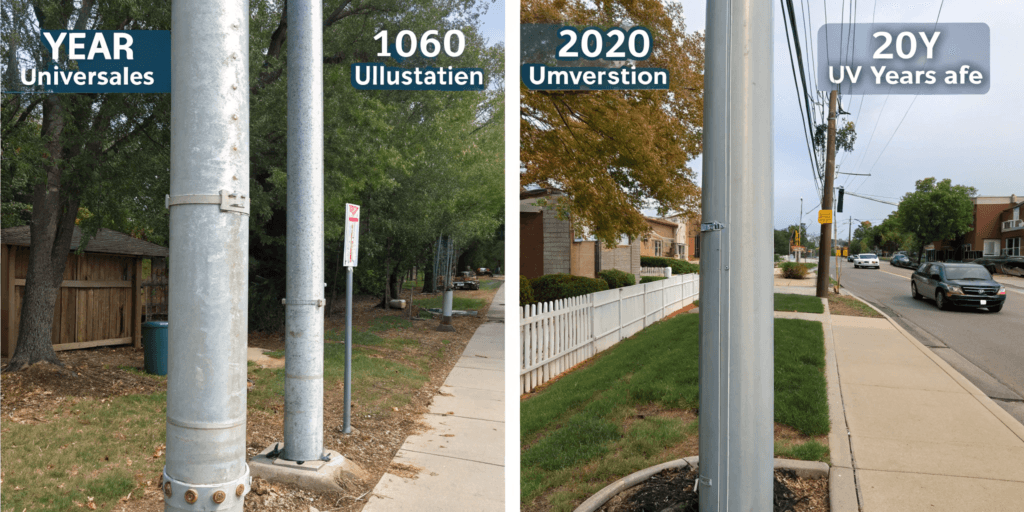

Maintenance and Longevity Considerations?

You want a pole that lasts—but also doesn’t drain your maintenance budget.

Aluminum wins on long lifespan, while fiberglass offers simplicity in corrosive environments.

What to consider:

- Aluminum lasts 50+ years with periodic cleaning or recoating

- Fiberglass lasts 15–20 years, but performs better near salt or fertilizer

- Both resist peeling, rust, and chipping

- Aluminum may need repainting after 20–30 years

- Fiberglass can fade slightly in UV-heavy areas over time

- Total cost of ownership includes: material, installation, maintenance, and lifespan

Ask an Expert: How to Choose the Right Pole?

Still unsure which material suits your location or budget? Let’s talk.

Our team at Huaweilight has helped hundreds of municipalities, contractors, and developers pick the right poles for their projects across Africa and beyond.

- Need help choosing between fiberglass and aluminum?

- Want a quote tailored to your specs?

- Wondering how to combine lighting, poles, and solar power?

📩 Reach out through our contact form or message us directly.

Let’s match your project with the pole that performs best.

Conclusion: Durable, Stylish Lighting That Fits Your Environment

Aluminum and fiberglass poles each bring strengths—aluminum lasts longer and offers more structural options, while fiberglass resists the harshest conditions. The best choice depends on your location, budget, and installation preferences. Need help deciding? Contact us for expert support and a quote that fits your goals.