Outdoor pole lighting is essential for keeping streets, walkways, and commercial spaces safe and visible. But even small issues—if ignored—can lead to bigger risks.

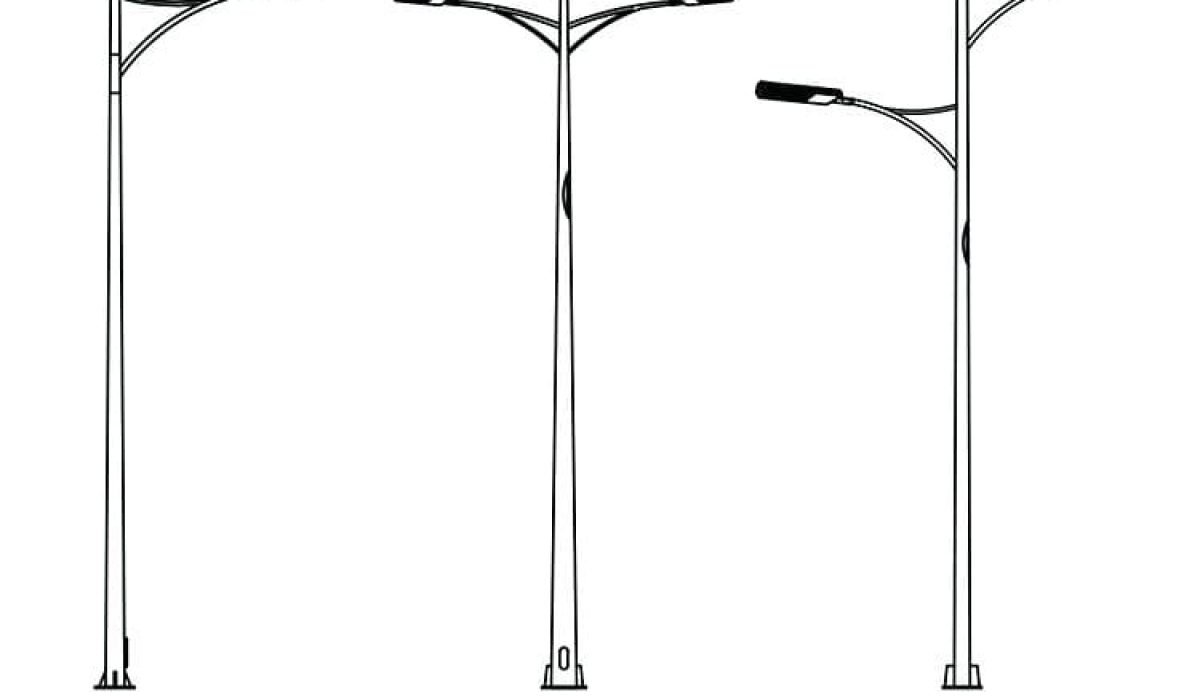

From rust to mismatched installations, outdoor pole lighting problems can be solved with the right materials, planning, and maintenance approach.

This article breaks down common issues I’ve seen in the field—and how you can avoid or fix them before they become serious hazards.

Why Outdoor Pole Lighting Matters?

Pole lighting does more than just light up the night—it protects people, property, and public spaces.

Properly installed lighting improves safety, deters crime, and enhances visibility. Poor maintenance or setup leads to costly failures and risks.

Neglecting small problems like corrosion or wiring faults can lead to outages, liability issues, or expensive rework. That’s why every detail matters—from the base plate to the bulb.

Common Problems with Outdoor Pole Lighting and How to Fix Them?

Outdoor poles deal with rain, wind, traffic, and time. It’s no surprise they develop problems—but most have simple fixes.

Common issues include mismatched bolts, rust, poor light coverage, and base damage. Each has a cost-effective solution.

Here’s a breakdown of the most frequent issues I’ve encountered:

-

1. Mismatched Bolt Patterns or Wrong Base Plate

Issue: New poles don’t fit the anchor bolts in old concrete foundations.

Solution: Use anchor bolt templates when ordering new poles or install pole adapters to bridge the mismatch. -

2. Worn or Damaged Light Pole Base

Issue: Bases get dented, scratched, or faded from cars, foot traffic, or weather.

Solution: Decorative base covers or powder-coated sleeves restore looks and offer added protection. -

3. Rust and Corrosion at Ground Level

Issue: Metal at the base rusts due to water exposure and minor damage.

Solution: Use aluminum or fiberglass poles that won’t rust. Base covers can conceal short-term damage but won’t stop corrosion. -

4. Insufficient Light Output

Issue: The area stays dim, leaving dark spots that reduce safety.

Solution: Switch to high-lumen LED fixtures, recheck pole spacing, or reposition lights for better coverage.

Other Potential Pole Lighting Issues?

Even when poles are properly installed, smaller failures can still happen over time.

Issues like flickering, leaning, or control failures often result from environmental wear or outdated components.

Here’s what else to watch for:

- Flickering lights → Often caused by loose wiring, driver failure, or voltage inconsistency.

- Leaning poles → Caused by poor foundations or soil erosion beneath the base.

- Light sensor/timer malfunction → Results in lights staying on during the day or failing to activate at night.

- Burnt-out bulbs or drivers → Even LEDs can fail over time. Replacements should match wattage and voltage specs.

- Open or damaged access panels → Exposed wiring can pose electrical hazards. Use vandal-resistant fasteners.

How to Prevent These Problems?

Most failures start small. Regular checks and the right material choices go a long way.

Routine inspections, corrosion-resistant materials, and experienced installation prevent most outdoor lighting issues.

Tips that work:

- Inspect poles every 6 months—check for rust, leaning, open access panels, or dimming.

- Clean lenses and fixtures to maintain brightness.

- Choose aluminum or fiberglass poles in humid or coastal areas.

- Secure all hand-holes and access panels with tamper-proof screws.

- Use surge protection devices to safeguard LED drivers and control circuits.

- Always work with certified installers who understand code requirements.

Why Professional Installation & Repairs Matter?

Cutting corners during installation causes problems down the road—sometimes dangerous ones.

Professional installers align poles with local codes, use the right hardware, and ensure long-term performance.

Reasons to trust an expert:

- They ensure pole foundations match structural loads and wind zones.

- They understand how to prevent galvanic corrosion during mixed-material installs.

- They install proper grounding and surge protection.

- They select compatible fixtures and drivers for your voltage and lighting plan.

- They minimize the risk of rework or safety violations.

Poor installs often cost double when issues are discovered later.

Why Choose a Local Expert in West Palm Beach?

Your location affects your lighting.

A local contractor understands the unique challenges of Florida’s coastal climate, regulations, and soil conditions.

Benefits of going local:

- Faster Response: Quick scheduling and emergency support.

- Climate Knowledge: Salt air speeds corrosion—locals know which materials hold up.

- Permit Experience: They handle code compliance and permitting.

- Support for Commercial Properties: Tailored solutions for parking lots, campuses, or HOA neighborhoods.

Ask if your contractor offers maintenance packages—they’re worth it.

Conclusion: Safe, Efficient Lighting Starts with Smart Choices

Fixing pole lighting issues early prevents accidents, saves money, and keeps your property secure.

If you’re seeing signs of failure—or planning an upgrade—work with a licensed expert who knows what really matters on-site.

FAQs

What causes rust at the base of light poles?

Water exposure, road salts, and surface damage allow rust to form—especially on steel poles.

How do I match a new light pole to an existing base?

Use anchor bolt templates during planning. Adapters can help if the new pole has a different bolt pattern.

Can aluminum light poles rust?

No. Aluminum forms a protective oxide layer and won’t rust, making it ideal for wet or coastal areas.

What lighting is best for outdoor commercial properties?

High-lumen LED fixtures with adjustable optics and timers/sensors work best for visibility and energy savings.

How do I know if my pole lighting needs replacement?

Watch for rust, leaning, dimming, or repeated outages. If multiple issues appear, a full replacement may be more cost-effective than repairs.